Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The cle<strong>an</strong> syngas to Fischer-Tropsch productions portion <strong>of</strong> <strong>the</strong> Steinberg’s case study<br />

was scaled down to provide mass flow rates <strong>for</strong> <strong>the</strong> FTD design. Though Steynberg et al. case<br />

study provides a mass <strong>an</strong>d energy bal<strong>an</strong>ce, assumptions <strong>an</strong>d back calculations were necessary to<br />

provide adequate data to scale down <strong>the</strong> design. The syngas gas used in <strong>the</strong> Steynberg et al. case<br />

study is given in Table D.2. Using <strong>the</strong> mole % data giving in Table D.2, <strong>an</strong>d <strong>the</strong> volumetric flow<br />

rate <strong>of</strong> cle<strong>an</strong> syngas from Table D.1, <strong>the</strong> mass flow rate <strong>of</strong> syngas from <strong>the</strong> Steynberg et al. case<br />

study was calculated to be 395.5 kg/s.<br />

Table D.2: Syngas gas used in <strong>the</strong> Steynberg et al. case study [72].<br />

Species mole %<br />

29.26<br />

H 2<br />

CO 37.36<br />

CO2 13.3<br />

0.16<br />

CH 4<br />

H 2O 19.43<br />

Inert 0.49<br />

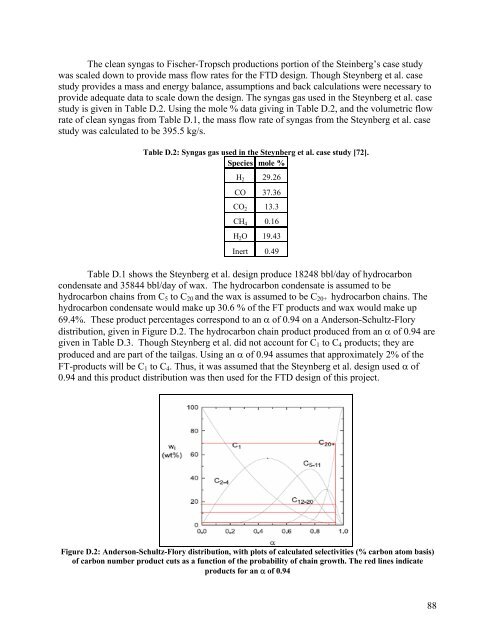

Table D.1 shows <strong>the</strong> Steynberg et al. design produce 18248 bbl/day <strong>of</strong> hydrocarbon<br />

condensate <strong>an</strong>d 35844 bbl/day <strong>of</strong> wax. The hydrocarbon condensate is assumed to be<br />

hydrocarbon chains from C5 to C20 <strong>an</strong>d <strong>the</strong> wax is assumed to be C20+ hydrocarbon chains. The<br />

hydrocarbon condensate would make up 30.6 % <strong>of</strong> <strong>the</strong> FT products <strong>an</strong>d wax would make up<br />

69.4%. These product percentages correspond to <strong>an</strong> α <strong>of</strong> 0.94 on a Anderson-Schultz-Flory<br />

distribution, given in Figure D.2. The hydrocarbon chain product produced from <strong>an</strong> α <strong>of</strong> 0.94 are<br />

given in Table D.3. Though Steynberg et al. did not account <strong>for</strong> C1 to C4 products; <strong>the</strong>y are<br />

produced <strong>an</strong>d are part <strong>of</strong> <strong>the</strong> tailgas. Using <strong>an</strong> α <strong>of</strong> 0.94 assumes that approximately 2% <strong>of</strong> <strong>the</strong><br />

FT-products will be C1 to C4. Thus, it was assumed that <strong>the</strong> Steynberg et al. design used α <strong>of</strong><br />

0.94 <strong>an</strong>d this product distribution was <strong>the</strong>n used <strong>for</strong> <strong>the</strong> FTD design <strong>of</strong> this project.<br />

Figure D.2: Anderson-Schultz-Flory distribution, with plots <strong>of</strong> calculated selectivities (% carbon atom basis)<br />

<strong>of</strong> carbon number product cuts as a function <strong>of</strong> <strong>the</strong> probability <strong>of</strong> chain growth. The red lines indicate<br />

products <strong>for</strong> <strong>an</strong> α <strong>of</strong> 0.94<br />

88