Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4. <strong>Design</strong> Summary<br />

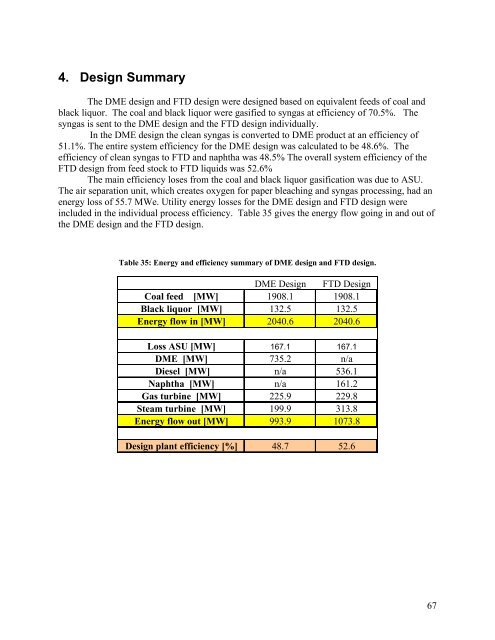

The DME design <strong>an</strong>d FTD design were designed based on equivalent feeds <strong>of</strong> coal <strong>an</strong>d<br />

black liquor. The coal <strong>an</strong>d black liquor were gasified to syngas at efficiency <strong>of</strong> 70.5%. The<br />

syngas is sent to <strong>the</strong> DME design <strong>an</strong>d <strong>the</strong> FTD design individually.<br />

In <strong>the</strong> DME design <strong>the</strong> cle<strong>an</strong> syngas is converted to DME product at <strong>an</strong> efficiency <strong>of</strong><br />

51.1%. The entire system efficiency <strong>for</strong> <strong>the</strong> DME design was calculated to be 48.6%. The<br />

efficiency <strong>of</strong> cle<strong>an</strong> syngas to FTD <strong>an</strong>d naphtha was 48.5% The overall system efficiency <strong>of</strong> <strong>the</strong><br />

FTD design from feed stock to FTD liquids was 52.6%<br />

The main efficiency loses from <strong>the</strong> coal <strong>an</strong>d black liquor gasification was due to ASU.<br />

The air separation unit, which creates oxygen <strong>for</strong> paper bleaching <strong>an</strong>d syngas processing, had <strong>an</strong><br />

energy loss <strong>of</strong> 55.7 MWe. Utility energy losses <strong>for</strong> <strong>the</strong> DME design <strong>an</strong>d FTD design were<br />

included in <strong>the</strong> individual process efficiency. Table 35 gives <strong>the</strong> energy flow going in <strong>an</strong>d out <strong>of</strong><br />

<strong>the</strong> DME design <strong>an</strong>d <strong>the</strong> FTD design.<br />

Table 35: Energy <strong>an</strong>d efficiency summary <strong>of</strong> DME design <strong>an</strong>d FTD design.<br />

DME <strong>Design</strong> FTD <strong>Design</strong><br />

Coal feed [MW] 1908.1 1908.1<br />

Black liquor [MW] 132.5 132.5<br />

Energy flow in [MW] 2040.6 2040.6<br />

Loss ASU [MW] 167.1 167.1<br />

DME [MW] 735.2 n/a<br />

Diesel [MW] n/a 536.1<br />

Naphtha [MW] n/a 161.2<br />

Gas turbine [MW] 225.9 229.8<br />

Steam turbine [MW] 199.9 313.8<br />

Energy flow out [MW] 993.9 1073.8<br />

<strong>Design</strong> pl<strong>an</strong>t efficiency [%] 48.7 52.6<br />

67