Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

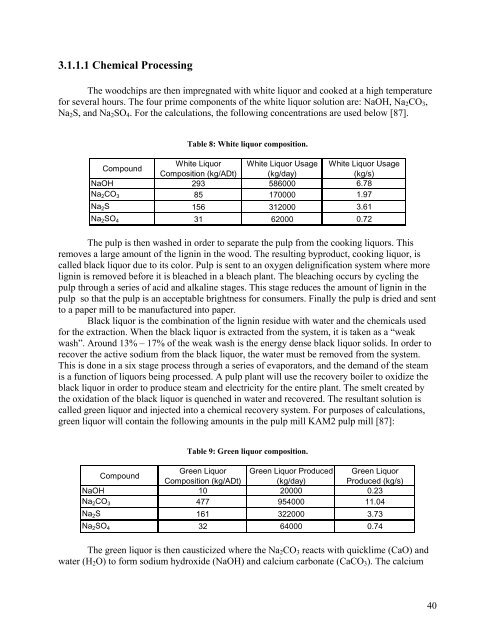

3.1.1.1 Chemical Processing<br />

The woodchips are <strong>the</strong>n impregnated with white liquor <strong>an</strong>d cooked at a high temperature<br />

<strong>for</strong> several hours. The four prime components <strong>of</strong> <strong>the</strong> white liquor solution are: NaOH, Na2CO3,<br />

Na2S, <strong>an</strong>d Na2SO4. For <strong>the</strong> calculations, <strong>the</strong> following concentrations are used below [87].<br />

Table 8: White liquor composition.<br />

Compound<br />

White Liquor<br />

Composition (kg/ADt)<br />

White Liquor Usage<br />

(kg/day)<br />

White Liquor Usage<br />

(kg/s)<br />

NaOH 293 586000 6.78<br />

Na2CO3 85 170000 1.97<br />

Na2S 156 312000 3.61<br />

Na2SO4 31 62000 0.72<br />

The pulp is <strong>the</strong>n washed in order to separate <strong>the</strong> pulp from <strong>the</strong> cooking liquors. This<br />

removes a large amount <strong>of</strong> <strong>the</strong> lignin in <strong>the</strong> wood. The resulting byproduct, cooking liquor, is<br />

called black liquor due to its color. <strong>Pulp</strong> is sent to <strong>an</strong> oxygen delignification system where more<br />

lignin is removed be<strong>for</strong>e it is bleached in a bleach pl<strong>an</strong>t. The bleaching occurs by cycling <strong>the</strong><br />

pulp through a series <strong>of</strong> acid <strong>an</strong>d alkaline stages. This stage reduces <strong>the</strong> amount <strong>of</strong> lignin in <strong>the</strong><br />

pulp so that <strong>the</strong> pulp is <strong>an</strong> acceptable brightness <strong>for</strong> consumers. Finally <strong>the</strong> pulp is dried <strong>an</strong>d sent<br />

to a paper mill to be m<strong>an</strong>ufactured into paper.<br />

Black liquor is <strong>the</strong> combination <strong>of</strong> <strong>the</strong> lignin residue with water <strong>an</strong>d <strong>the</strong> chemicals used<br />

<strong>for</strong> <strong>the</strong> extraction. When <strong>the</strong> black liquor is extracted from <strong>the</strong> system, it is taken as a “weak<br />

wash”. Around 13% – 17% <strong>of</strong> <strong>the</strong> weak wash is <strong>the</strong> energy dense black liquor solids. In order to<br />

recover <strong>the</strong> active sodium from <strong>the</strong> black liquor, <strong>the</strong> water must be removed from <strong>the</strong> system.<br />

This is done in a six stage process through a series <strong>of</strong> evaporators, <strong>an</strong>d <strong>the</strong> dem<strong>an</strong>d <strong>of</strong> <strong>the</strong> steam<br />

is a function <strong>of</strong> liquors being processed. A pulp pl<strong>an</strong>t will use <strong>the</strong> recovery boiler to oxidize <strong>the</strong><br />

black liquor in order to produce steam <strong>an</strong>d electricity <strong>for</strong> <strong>the</strong> entire pl<strong>an</strong>t. The smelt created by<br />

<strong>the</strong> oxidation <strong>of</strong> <strong>the</strong> black liquor is quenched in water <strong>an</strong>d recovered. The result<strong>an</strong>t solution is<br />

called green liquor <strong>an</strong>d injected into a chemical recovery system. For purposes <strong>of</strong> calculations,<br />

green liquor will contain <strong>the</strong> following amounts in <strong>the</strong> pulp mill KAM2 pulp mill [87]:<br />

Table 9: Green liquor composition.<br />

Compound<br />

Green Liquor<br />

Composition (kg/ADt)<br />

Green Liquor Produced<br />

(kg/day)<br />

Green Liquor<br />

Produced (kg/s)<br />

NaOH 10 20000 0.23<br />

Na2CO3 477 954000 11.04<br />

Na2S 161 322000 3.73<br />

Na2SO4 32 64000 0.74<br />

The green liquor is <strong>the</strong>n causticized where <strong>the</strong> Na2CO3 reacts with quicklime (CaO) <strong>an</strong>d<br />

water (H2O) to <strong>for</strong>m sodium hydroxide (NaOH) <strong>an</strong>d calcium carbonate (CaCO3). The calcium<br />

40