Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

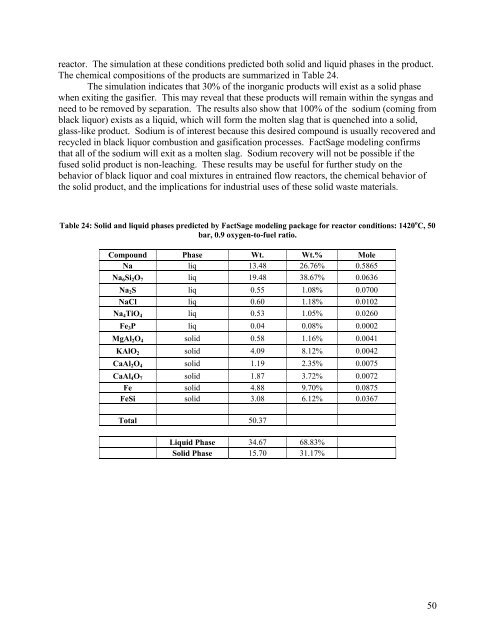

eactor. The simulation at <strong>the</strong>se conditions predicted both solid <strong>an</strong>d liquid phases in <strong>the</strong> product.<br />

The chemical compositions <strong>of</strong> <strong>the</strong> products are summarized in Table 24.<br />

The simulation indicates that 30% <strong>of</strong> <strong>the</strong> inorg<strong>an</strong>ic products will exist as a solid phase<br />

when exiting <strong>the</strong> gasifier. This may reveal that <strong>the</strong>se products will remain within <strong>the</strong> syngas <strong>an</strong>d<br />

need to be removed by separation. The results also show that 100% <strong>of</strong> <strong>the</strong> sodium (coming from<br />

black liquor) exists as a liquid, which will <strong>for</strong>m <strong>the</strong> molten slag that is quenched into a solid,<br />

glass-like product. Sodium is <strong>of</strong> interest because this desired compound is usually recovered <strong>an</strong>d<br />

recycled in black liquor combustion <strong>an</strong>d gasification processes. FactSage modeling confirms<br />

that all <strong>of</strong> <strong>the</strong> sodium will exit as a molten slag. Sodium recovery will not be possible if <strong>the</strong><br />

fused solid product is non-leaching. These results may be useful <strong>for</strong> fur<strong>the</strong>r study on <strong>the</strong><br />

behavior <strong>of</strong> black liquor <strong>an</strong>d coal mixtures in entrained flow reactors, <strong>the</strong> chemical behavior <strong>of</strong><br />

<strong>the</strong> solid product, <strong>an</strong>d <strong>the</strong> implications <strong>for</strong> industrial uses <strong>of</strong> <strong>the</strong>se solid waste materials.<br />

Table 24: Solid <strong>an</strong>d liquid phases predicted by FactSage modeling package <strong>for</strong> reactor conditions: 1420 o C, 50<br />

bar, 0.9 oxygen-to-fuel ratio.<br />

Compound Phase Wt. Wt.% Mole<br />

Na liq 13.48 26.76% 0.5865<br />

Na6Si2O7 liq 19.48 38.67% 0.0636<br />

Na2S liq 0.55 1.08% 0.0700<br />

NaCl liq 0.60 1.18% 0.0102<br />

Na4TiO4 liq 0.53 1.05% 0.0260<br />

Fe3P liq 0.04 0.08% 0.0002<br />

MgAl2O4 solid 0.58 1.16% 0.0041<br />

KAlO2 solid 4.09 8.12% 0.0042<br />

CaAl2O4 solid 1.19 2.35% 0.0075<br />

CaAl4O7 solid 1.87 3.72% 0.0072<br />

Fe solid 4.88 9.70% 0.0875<br />

FeSi solid 3.08 6.12% 0.0367<br />

Total 50.37<br />

Liquid Phase 34.67 68.83%<br />

Solid Phase 15.70 31.17%<br />

50