Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

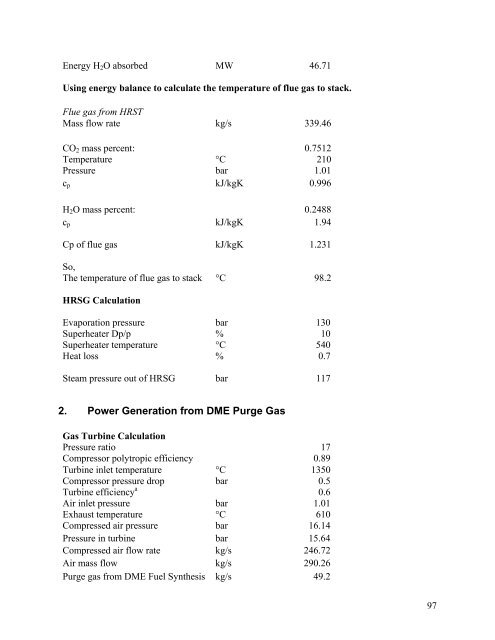

Energy H2O absorbed MW 46.71<br />

Using energy bal<strong>an</strong>ce to calculate <strong>the</strong> temperature <strong>of</strong> flue gas to stack.<br />

Flue gas from HRST<br />

Mass flow rate kg/s 339.46<br />

CO2 mass percent: 0.7512<br />

Temperature °C 210<br />

Pressure bar 1.01<br />

cp kJ/kgK 0.996<br />

H2O mass percent: 0.2488<br />

cp kJ/kgK 1.94<br />

Cp <strong>of</strong> flue gas kJ/kgK 1.231<br />

So,<br />

The temperature <strong>of</strong> flue gas to stack °C 98.2<br />

HRSG Calculation<br />

Evaporation pressure bar 130<br />

Superheater Dp/p % 10<br />

Superheater temperature °C 540<br />

Heat loss % 0.7<br />

Steam pressure out <strong>of</strong> HRSG bar 117<br />

2. Power Generation from DME Purge Gas<br />

Gas Turbine Calculation<br />

Pressure ratio 17<br />

Compressor polytropic efficiency 0.89<br />

Turbine inlet temperature °C 1350<br />

Compressor pressure drop bar 0.5<br />

Turbine efficiency a 0.6<br />

Air inlet pressure bar 1.01<br />

Exhaust temperature °C 610<br />

Compressed air pressure bar 16.14<br />

Pressure in turbine bar 15.64<br />

Compressed air flow rate kg/s 246.72<br />

Air mass flow kg/s 290.26<br />

Purge gas from DME Fuel Syn<strong>the</strong>sis kg/s 49.2<br />

97