Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

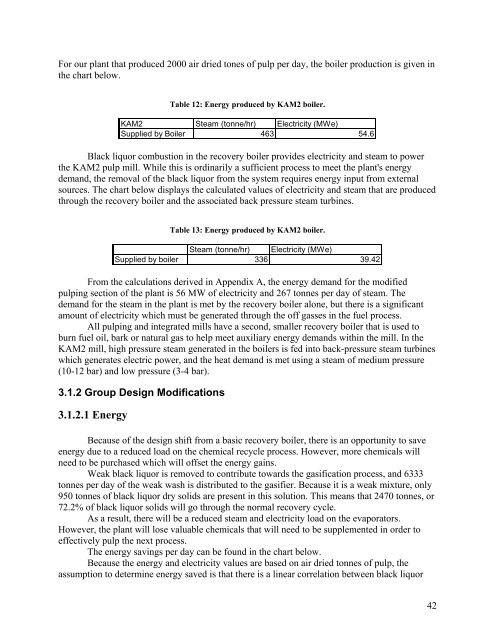

For our pl<strong>an</strong>t that produced 2000 air dried tones <strong>of</strong> pulp per day, <strong>the</strong> boiler production is given in<br />

<strong>the</strong> chart below.<br />

Table 12: Energy produced by KAM2 boiler.<br />

KAM2 Steam (tonne/hr) Electricity (MWe)<br />

Supplied by Boiler 463 54.6<br />

Black liquor combustion in <strong>the</strong> recovery boiler provides electricity <strong>an</strong>d steam to power<br />

<strong>the</strong> KAM2 pulp mill. While this is ordinarily a sufficient process to meet <strong>the</strong> pl<strong>an</strong>t's energy<br />

dem<strong>an</strong>d, <strong>the</strong> removal <strong>of</strong> <strong>the</strong> black liquor from <strong>the</strong> system requires energy input from external<br />

sources. The chart below displays <strong>the</strong> calculated values <strong>of</strong> electricity <strong>an</strong>d steam that are produced<br />

through <strong>the</strong> recovery boiler <strong>an</strong>d <strong>the</strong> associated back pressure steam turbines.<br />

Table 13: Energy produced by KAM2 boiler.<br />

Steam (tonne/hr) Electricity (MWe)<br />

Supplied by boiler 336 39.42<br />

From <strong>the</strong> calculations derived in Appendix A, <strong>the</strong> energy dem<strong>an</strong>d <strong>for</strong> <strong>the</strong> modified<br />

pulping section <strong>of</strong> <strong>the</strong> pl<strong>an</strong>t is 56 MW <strong>of</strong> electricity <strong>an</strong>d 267 tonnes per day <strong>of</strong> steam. The<br />

dem<strong>an</strong>d <strong>for</strong> <strong>the</strong> steam in <strong>the</strong> pl<strong>an</strong>t is met by <strong>the</strong> recovery boiler alone, but <strong>the</strong>re is a signific<strong>an</strong>t<br />

amount <strong>of</strong> electricity which must be generated through <strong>the</strong> <strong>of</strong>f gasses in <strong>the</strong> fuel process.<br />

All pulping <strong>an</strong>d integrated mills have a second, smaller recovery boiler that is used to<br />

burn fuel oil, bark or natural gas to help meet auxiliary energy dem<strong>an</strong>ds within <strong>the</strong> mill. In <strong>the</strong><br />

KAM2 mill, high pressure steam generated in <strong>the</strong> boilers is fed into back-pressure steam turbines<br />

which generates electric power, <strong>an</strong>d <strong>the</strong> heat dem<strong>an</strong>d is met using a steam <strong>of</strong> medium pressure<br />

(10-12 bar) <strong>an</strong>d low pressure (3-4 bar).<br />

3.1.2 Group <strong>Design</strong> Modifications<br />

3.1.2.1 Energy<br />

Because <strong>of</strong> <strong>the</strong> design shift from a basic recovery boiler, <strong>the</strong>re is <strong>an</strong> opportunity to save<br />

energy due to a reduced load on <strong>the</strong> chemical recycle process. However, more chemicals will<br />

need to be purchased which will <strong>of</strong>fset <strong>the</strong> energy gains.<br />

Weak black liquor is removed to contribute towards <strong>the</strong> gasification process, <strong>an</strong>d 6333<br />

tonnes per day <strong>of</strong> <strong>the</strong> weak wash is distributed to <strong>the</strong> gasifier. Because it is a weak mixture, only<br />

950 tonnes <strong>of</strong> black liquor dry solids are present in this solution. This me<strong>an</strong>s that 2470 tonnes, or<br />

72.2% <strong>of</strong> black liquor solids will go through <strong>the</strong> normal recovery cycle.<br />

As a result, <strong>the</strong>re will be a reduced steam <strong>an</strong>d electricity load on <strong>the</strong> evaporators.<br />

However, <strong>the</strong> pl<strong>an</strong>t will lose valuable chemicals that will need to be supplemented in order to<br />

effectively pulp <strong>the</strong> next process.<br />

The energy savings per day c<strong>an</strong> be found in <strong>the</strong> chart below.<br />

Because <strong>the</strong> energy <strong>an</strong>d electricity values are based on air dried tonnes <strong>of</strong> pulp, <strong>the</strong><br />

assumption to determine energy saved is that <strong>the</strong>re is a linear correlation between black liquor<br />

42