Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DME<br />

Density = 0.67 kg/L (at 20 °C)<br />

Calorific value = 28.98 MJ/kg<br />

1 barrel = 42 gallons = 159 liter<br />

1 J/s = 10 -6 MWt<br />

⎛<br />

⎜<br />

⎝<br />

2198.78tons<br />

day<br />

⎞<br />

⎟<br />

⎠<br />

1000kg ⎛ ⎞<br />

⎜ ⎟<br />

⎝ ton ⎠<br />

28.98x106 ⎛ J ⎞<br />

⎜ ⎟ = 63517.8<br />

⎝ day ⎠<br />

GJ<br />

day<br />

Assuming a cold gas efficiency <strong>of</strong> DME production is 51.1%, <strong>the</strong> syngas energy required:<br />

The syngas mass requirement:<br />

63517.8 GJ<br />

⎛<br />

⎞<br />

⎜<br />

⎟<br />

⎝ day ⎠<br />

0.51<br />

=124228 GJ<br />

day<br />

⎛ 124228GJ⎞<br />

⎜ ⎟<br />

⎝ day ⎠<br />

1000MJ ⎛ ⎞<br />

⎜ ⎟<br />

⎝ GJ ⎠<br />

1kg ⎛ ⎞ ⎛ ton ⎞<br />

⎜ ⎟ ⎜ ⎟ =10629<br />

⎝ 11.6MJ ⎠ ⎝ 1000kg⎠<br />

ton<br />

day<br />

=123 kg<br />

s<br />

The syngas yield is known, but <strong>the</strong> amount <strong>of</strong> fuel required to generate a mass <strong>of</strong> syngas is<br />

unknown.<br />

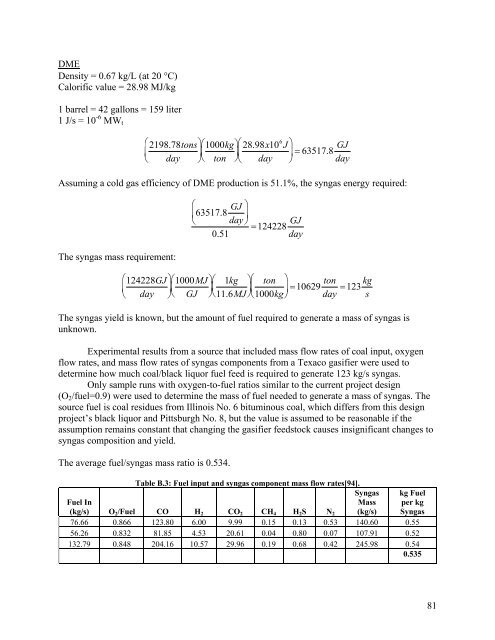

Experimental results from a source that included mass flow rates <strong>of</strong> coal input, oxygen<br />

flow rates, <strong>an</strong>d mass flow rates <strong>of</strong> syngas components from a Texaco gasifier were used to<br />

determine how much coal/black liquor fuel feed is required to generate 123 kg/s syngas.<br />

Only sample runs with oxygen-to-fuel ratios similar to <strong>the</strong> current project design<br />

(O2/fuel=0.9) were used to determine <strong>the</strong> mass <strong>of</strong> fuel needed to generate a mass <strong>of</strong> syngas. The<br />

source fuel is coal residues from Illinois No. 6 bituminous coal, which differs from this design<br />

project’s black liquor <strong>an</strong>d Pittsburgh No. 8, but <strong>the</strong> value is assumed to be reasonable if <strong>the</strong><br />

assumption remains const<strong>an</strong>t that ch<strong>an</strong>ging <strong>the</strong> gasifier feedstock causes insignific<strong>an</strong>t ch<strong>an</strong>ges to<br />

syngas composition <strong>an</strong>d yield.<br />

The average fuel/syngas mass ratio is 0.534.<br />

Table B.3: Fuel input <strong>an</strong>d syngas component mass flow rates[94].<br />

Syngas kg Fuel<br />

Fuel In<br />

Mass per kg<br />

(kg/s) O2/Fuel CO H2 CO2 CH4 H2S N2 (kg/s) Syngas<br />

76.66 0.866 123.80 6.00 9.99 0.15 0.13 0.53 140.60 0.55<br />

56.26 0.832 81.85 4.53 20.61 0.04 0.80 0.07 107.91 0.52<br />

132.79 0.848 204.16 10.57 29.96 0.19 0.68 0.42 245.98 0.54<br />

0.535<br />

81