Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

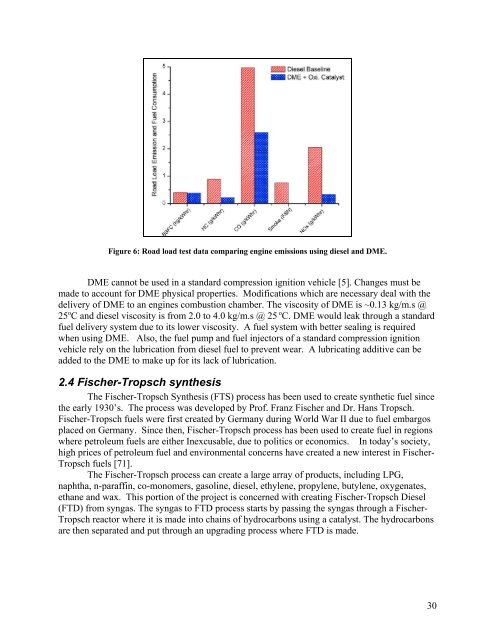

Figure 6: Road load test data comparing engine emissions using diesel <strong>an</strong>d DME.<br />

DME c<strong>an</strong>not be used in a st<strong>an</strong>dard compression ignition vehicle [5]. Ch<strong>an</strong>ges must be<br />

made to account <strong>for</strong> DME physical properties. Modifications which are necessary deal with <strong>the</strong><br />

delivery <strong>of</strong> DME to <strong>an</strong> engines combustion chamber. The viscosity <strong>of</strong> DME is ~0.13 kg/m.s @<br />

25 o C <strong>an</strong>d diesel viscosity is from 2.0 to 4.0 kg/m.s @ 25 o C. DME would leak through a st<strong>an</strong>dard<br />

fuel delivery system due to its lower viscosity. A fuel system with better sealing is required<br />

when using DME. Also, <strong>the</strong> fuel pump <strong>an</strong>d fuel injectors <strong>of</strong> a st<strong>an</strong>dard compression ignition<br />

vehicle rely on <strong>the</strong> lubrication from diesel fuel to prevent wear. A lubricating additive c<strong>an</strong> be<br />

added to <strong>the</strong> DME to make up <strong>for</strong> its lack <strong>of</strong> lubrication.<br />

2.4 Fischer-Tropsch syn<strong>the</strong>sis<br />

The Fischer-Tropsch Syn<strong>the</strong>sis (FTS) process has been used to create syn<strong>the</strong>tic fuel since<br />

<strong>the</strong> early 1930’s. The process was developed by Pr<strong>of</strong>. Fr<strong>an</strong>z Fischer <strong>an</strong>d Dr. H<strong>an</strong>s Tropsch.<br />

Fischer-Tropsch fuels were first created by Germ<strong>an</strong>y during World War II due to fuel embargos<br />

placed on Germ<strong>an</strong>y. Since <strong>the</strong>n, Fischer-Tropsch process has been used to create fuel in regions<br />

where petroleum fuels are ei<strong>the</strong>r Inexcusable, due to politics or economics. In today’s society,<br />

high prices <strong>of</strong> petroleum fuel <strong>an</strong>d environmental concerns have created a new interest in Fischer-<br />

Tropsch fuels [71].<br />

The Fischer-Tropsch process c<strong>an</strong> create a large array <strong>of</strong> products, including LPG,<br />

naphtha, n-paraffin, co-monomers, gasoline, diesel, ethylene, propylene, butylene, oxygenates,<br />

eth<strong>an</strong>e <strong>an</strong>d wax. This portion <strong>of</strong> <strong>the</strong> project is concerned with creating Fischer-Tropsch Diesel<br />

(FTD) from syngas. The syngas to FTD process starts by passing <strong>the</strong> syngas through a Fischer-<br />

Tropsch reactor where it is made into chains <strong>of</strong> hydrocarbons using a catalyst. The hydrocarbons<br />

are <strong>the</strong>n separated <strong>an</strong>d put through <strong>an</strong> upgrading process where FTD is made.<br />

30