Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Enthalpy MJ/kg 2.7895<br />

Energy <strong>of</strong> MP Steam used MW 6.41<br />

LP Steam Heat Exch<strong>an</strong>ger<br />

LP Steam<br />

Temperature °C 156<br />

Pressure bar 4.5<br />

Flow Rate kg/s 4.3<br />

cp kJ/kgK 2.339<br />

Enthalpy MJ/kg 2.753<br />

Energy <strong>of</strong> LP Steam used MW 0.36<br />

Mass flow rate <strong>of</strong> steam <strong>for</strong> ST:<br />

Available Energy MW 173.05<br />

Steam Property<br />

Temperature °C 540<br />

Pressure bar 117<br />

cp kJ/kgK 2.5895<br />

So, mass flow rate kg/s 159.34<br />

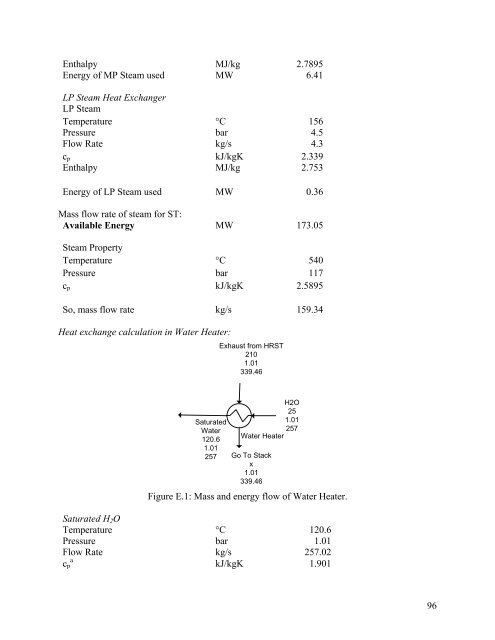

Heat exch<strong>an</strong>ge calculation in Water Heater:<br />

Saturated<br />

Water<br />

120.6<br />

1.01<br />

257<br />

Exhaust from HRST<br />

210<br />

1.01<br />

339.46<br />

H2O<br />

25<br />

1.01<br />

257<br />

Water Heater<br />

Go To Stack<br />

x<br />

1.01<br />

339.46<br />

Figure E.1: Mass <strong>an</strong>d energy flow <strong>of</strong> Water Heater.<br />

Saturated H2O<br />

Temperature °C 120.6<br />

Pressure bar 1.01<br />

Flow Rate kg/s 257.02<br />

cp a kJ/kgK 1.901<br />

96