Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

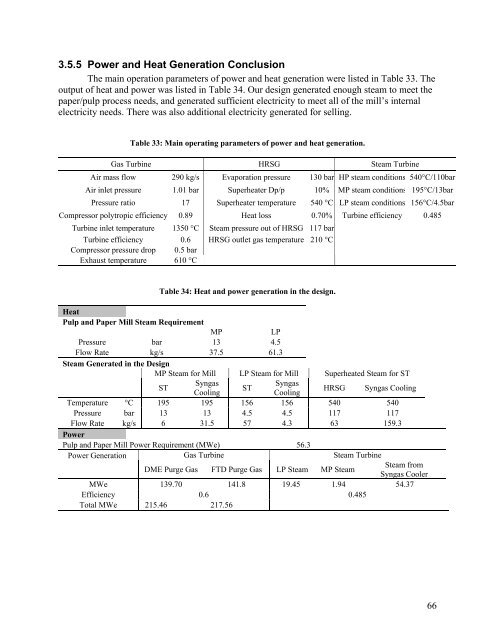

3.5.5 Power <strong>an</strong>d Heat Generation Conclusion<br />

The main operation parameters <strong>of</strong> power <strong>an</strong>d heat generation were listed in Table 33. The<br />

output <strong>of</strong> heat <strong>an</strong>d power was listed in Table 34. Our design generated enough steam to meet <strong>the</strong><br />

paper/pulp process needs, <strong>an</strong>d generated sufficient electricity to meet all <strong>of</strong> <strong>the</strong> mill’s internal<br />

electricity needs. There was also additional electricity generated <strong>for</strong> selling.<br />

Table 33: Main operating parameters <strong>of</strong> power <strong>an</strong>d heat generation.<br />

Gas Turbine HRSG Steam Turbine<br />

Air mass flow 290 kg/s Evaporation pressure 130 bar HP steam conditions 540°C/110bar<br />

Air inlet pressure 1.01 bar Superheater Dp/p 10% MP steam conditions 195°C/13bar<br />

Pressure ratio 17 Superheater temperature 540 °C LP steam conditions 156°C/4.5bar<br />

Compressor polytropic efficiency 0.89 Heat loss 0.70% Turbine efficiency 0.485<br />

Turbine inlet temperature 1350 °C Steam pressure out <strong>of</strong> HRSG 117 bar<br />

Turbine efficiency 0.6 HRSG outlet gas temperature 210 °C<br />

Compressor pressure drop 0.5 bar<br />

Exhaust temperature 610 °C<br />

Table 34: Heat <strong>an</strong>d power generation in <strong>the</strong> design.<br />

Heat<br />

<strong>Pulp</strong> <strong>an</strong>d Paper <strong>Mill</strong> Steam Requirement<br />

MP LP<br />

Pressure bar 13 4.5<br />

Flow Rate kg/s 37.5 61.3<br />

Steam Generated in <strong>the</strong> <strong>Design</strong><br />

MP Steam <strong>for</strong> <strong>Mill</strong> LP Steam <strong>for</strong> <strong>Mill</strong> Superheated Steam <strong>for</strong> ST<br />

ST<br />

Syngas<br />

Cooling<br />

ST<br />

Syngas<br />

Cooling<br />

HRSG Syngas Cooling<br />

Temperature °C 195 195 156 156 540 540<br />

Pressure bar 13 13 4.5 4.5 117 117<br />

Flow Rate<br />

Power<br />

kg/s 6 31.5 57 4.3 63 159.3<br />

<strong>Pulp</strong> <strong>an</strong>d Paper <strong>Mill</strong> Power Requirement (MWe) 56.3<br />

Power Generation Gas Turbine Steam Turbine<br />

DME Purge Gas FTD Purge Gas LP Steam MP Steam<br />

Steam from<br />

Syngas Cooler<br />

MWe 139.70 141.8 19.45 1.94 54.37<br />

Efficiency 0.6 0.485<br />

Total MWe 215.46 217.56<br />

66