Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

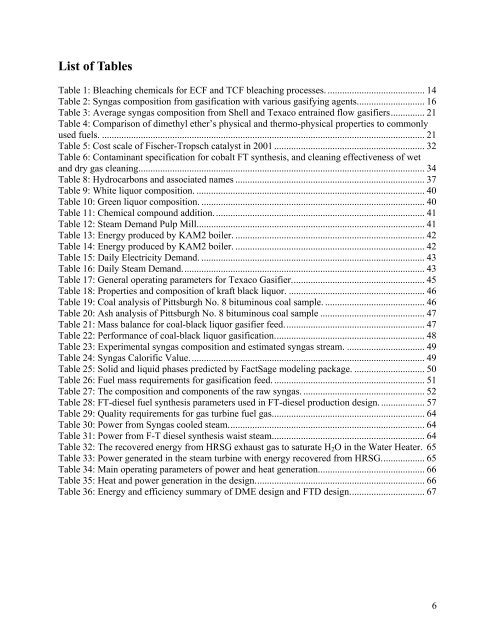

List <strong>of</strong> Tables<br />

Table 1: Bleaching chemicals <strong>for</strong> ECF <strong>an</strong>d TCF bleaching processes. ........................................ 14<br />

Table 2: Syngas composition from gasification with various gasifying agents. ........................... 16<br />

Table 3: Average syngas composition from Shell <strong>an</strong>d Texaco entrained flow gasifiers .............. 21<br />

Table 4: Comparison <strong>of</strong> dimethyl e<strong>the</strong>r’s physical <strong>an</strong>d <strong>the</strong>rmo-physical properties to commonly<br />

used fuels. ..................................................................................................................................... 21<br />

Table 5: Cost scale <strong>of</strong> Fischer-Tropsch catalyst in 2001 .............................................................. 32<br />

Table 6: Contamin<strong>an</strong>t specification <strong>for</strong> cobalt FT syn<strong>the</strong>sis, <strong>an</strong>d cle<strong>an</strong>ing effectiveness <strong>of</strong> wet<br />

<strong>an</strong>d dry gas cle<strong>an</strong>ing ...................................................................................................................... 34<br />

Table 8: Hydrocarbons <strong>an</strong>d associated names .............................................................................. 37<br />

Table 9: White liquor composition. .............................................................................................. 40<br />

Table 10: Green liquor composition. ............................................................................................ 40<br />

Table 11: Chemical compound addition. ...................................................................................... 41<br />

Table 12: Steam Dem<strong>an</strong>d <strong>Pulp</strong> <strong>Mill</strong>.............................................................................................. 41<br />

Table 13: Energy produced by KAM2 boiler. .............................................................................. 42<br />

Table 14: Energy produced by KAM2 boiler. .............................................................................. 42<br />

Table 15: Daily Electricity Dem<strong>an</strong>d. ............................................................................................ 43<br />

Table 16: Daily Steam Dem<strong>an</strong>d. ................................................................................................... 43<br />

Table 17: General operating parameters <strong>for</strong> Texaco Gasifier. ...................................................... 45<br />

Table 18: Properties <strong>an</strong>d composition <strong>of</strong> kraft black liquor. ........................................................ 46<br />

Table 19: Coal <strong>an</strong>alysis <strong>of</strong> Pittsburgh No. 8 bituminous coal sample. ......................................... 46<br />

Table 20: Ash <strong>an</strong>alysis <strong>of</strong> Pittsburgh No. 8 bituminous coal sample ........................................... 47<br />

Table 21: Mass bal<strong>an</strong>ce <strong>for</strong> coal-black liquor gasifier feed. ......................................................... 47<br />

Table 22: Per<strong>for</strong>m<strong>an</strong>ce <strong>of</strong> coal-black liquor gasification. ............................................................. 48<br />

Table 23: Experimental syngas composition <strong>an</strong>d estimated syngas stream. ................................ 49<br />

Table 24: Syngas Calorific Value. ................................................................................................ 49<br />

Table 25: Solid <strong>an</strong>d liquid phases predicted by FactSage modeling package. ............................. 50<br />

Table 26: Fuel mass requirements <strong>for</strong> gasification feed. .............................................................. 51<br />

Table 27: The composition <strong>an</strong>d components <strong>of</strong> <strong>the</strong> raw syngas. .................................................. 52<br />

Table 28: FT-diesel fuel syn<strong>the</strong>sis parameters used in FT-diesel production design. .................. 57<br />

Table 29: Quality requirements <strong>for</strong> gas turbine fuel gas. .............................................................. 64<br />

Table 30: Power from Syngas cooled steam. ................................................................................ 64<br />

Table 31: Power from F-T diesel syn<strong>the</strong>sis waist steam. .............................................................. 64<br />

Table 32: The recovered energy from HRSG exhaust gas to saturate H2O in <strong>the</strong> Water Heater. 65<br />

Table 33: Power generated in <strong>the</strong> steam turbine with energy recovered from HRSG. ................. 65<br />

Table 34: Main operating parameters <strong>of</strong> power <strong>an</strong>d heat generation. ........................................... 66<br />

Table 35: Heat <strong>an</strong>d power generation in <strong>the</strong> design. ..................................................................... 66<br />

Table 36: Energy <strong>an</strong>d efficiency summary <strong>of</strong> DME design <strong>an</strong>d FTD design. .............................. 67<br />

6