Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Novel Design of an Integrated Pulp Mill Biorefinery for the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cle<strong>an</strong> syngas<br />

123.0 kg/s<br />

1437.8 MW<br />

145 o C<br />

50 bar<br />

Cle<strong>an</strong> syngas<br />

123.0 kg/s<br />

1437.8 MW<br />

Tail gas<br />

91.5 kg/s<br />

118 o C<br />

29.4 bar<br />

Tail Gas<br />

60.4 kg/s<br />

492.9 MW<br />

260 o C<br />

30.3 bar<br />

Slurry-phase<br />

bubbling-bed<br />

reactor<br />

Steam<br />

96.3 kg/s<br />

86 o C<br />

10 bar<br />

Water<br />

96.3 kg/s<br />

15 o C<br />

10bar<br />

Steam<br />

128.8 kg/s<br />

2.846 MW<br />

260 o C<br />

38 bar<br />

Water<br />

15 o C<br />

38 bar<br />

Tail gas<br />

91.5 kg/s<br />

38 o C<br />

29.4 bar<br />

FT Liquid<br />

6.2 kg/s<br />

Condenser<br />

FT Liquid<br />

10.8 kg/s<br />

Unconverted syngas<br />

60.4 kg/s<br />

492.9 MW<br />

38 o C<br />

26.6bar<br />

Water<br />

20.3 kg/s<br />

Wax<br />

Hydrocracking<br />

Wax C20+<br />

11.9 kg/s<br />

FT Separator<br />

FT Product C1-C4<br />

0.6 kg/s<br />

46.0 MW<br />

Distillate C12–C20<br />

2.9 kg/s<br />

Naphtha C5–C11<br />

1.9 kg/s<br />

Diesel<br />

9.5 kg/s<br />

Naphtha<br />

1.8 kg/s<br />

Diesel<br />

12.4 kg/s<br />

8667.9 bbl/d<br />

536.1 MW<br />

Naphtha<br />

3.7 kg/s<br />

2552.9 bbl/d<br />

161.2 MW<br />

Figure<br />

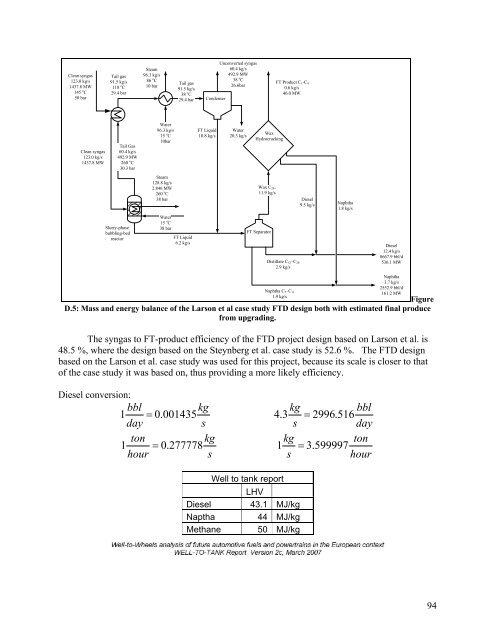

D.5: Mass <strong>an</strong>d energy bal<strong>an</strong>ce <strong>of</strong> <strong>the</strong> Larson et al case study FTD design both with estimated final produce<br />

from upgrading.<br />

The syngas to FT-product efficiency <strong>of</strong> <strong>the</strong> FTD project design based on Larson et al. is<br />

48.5 %, where <strong>the</strong> design based on <strong>the</strong> Steynberg et al. case study is 52.6 %. The FTD design<br />

based on <strong>the</strong> Larson et al. case study was used <strong>for</strong> this project, because its scale is closer to that<br />

<strong>of</strong> <strong>the</strong> case study it was based on, thus providing a more likely efficiency.<br />

Diesel conversion:<br />

bbl<br />

kg<br />

1 = 0.<br />

001435<br />

day<br />

s<br />

ton<br />

kg<br />

1 = 0.<br />

277778<br />

hour<br />

s<br />

Well to t<strong>an</strong>k report<br />

LHV<br />

Diesel 43.1 MJ/kg<br />

Naptha 44 MJ/kg<br />

Meth<strong>an</strong>e 50 MJ/kg<br />

kg<br />

bbl<br />

4 . 3 = 2996.<br />

516<br />

s<br />

day<br />

kg<br />

ton<br />

1 = 3.<br />

599997<br />

s<br />

hour<br />

94