36e Operator's Manual 2013.pdf - Marlow-Hunter, LLC

36e Operator's Manual 2013.pdf - Marlow-Hunter, LLC

36e Operator's Manual 2013.pdf - Marlow-Hunter, LLC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

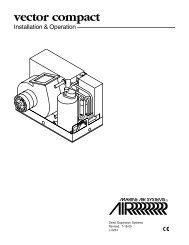

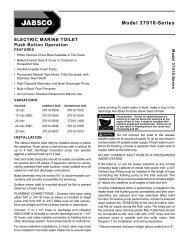

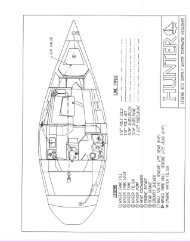

<strong>Hunter</strong> e36 • Engines and TransmissionsThe following is a list of components associated withyour engines and transmissions.••••••••EngineControlsEngine MonitoringEngine CoolingEmergency EquipmentEngine ExhaustTransmission (s)Shifters and Controls11.1 EnginesThe engine on your boat is at the heart of your boat.Proper attention to and maintenance of your enginewill assure you many hours of pleasurable, safeboating, and will prevent unnecessary engine problems.You must, therefore, become thoroughly familiarwith all aspects of the engines proper operationoutlined in the manufacturers Operator’s <strong>Manual</strong>s.A general maintenance program consists of proper lubrication,cleaning of fuel filters, fuel lines, and air filters.! CAUTION !Take proper care when washing down, or cleaningyour engines, that water does not enter the airintakes. Water in the air intakes may go directly tothe cylinders, resulting in rust and possibly internalengine damage.Fig. 11.1 shows you drive and components aboard yourboat.We strongly urge you to comply with the manual providedby the engine manufacturer. Follow the recommendedmaintenance and warranty schedule in theowner’s packet. Engine abuse or improper maintenancemay adversely affect the claims made under the independentwarranty provided by the engine manufacturer.The engine manual states the maximum RPM ratingestablished by the engine manufacturer for your boat’sengines. Do not exceed this rating. Check the manualfor other information about maximum RPM’s.Engines are selected and designed to meet or exceedindustry standards set by marine engine manufacturers.SYSTEMS SCHEMATIC FOR STERN DRIVE ENGINECOMPARTMENT ENCLOSUREBATT. SWITCHENGINEWATER INTAKEEXHAUSTFUEL SYSTEMFEEDRETURNTANKRUNNING GEARSHAFTCOUPLINGDRIPLESSTHRU-HULLSEA COCKSTRAINERELBOWHOSEMUFFLERFILTERVALVE @ TANKSEE ELEVATION BELOW FOR CABLES TO PEDESTALRETURN FUEL LINEFUEL FEED & FILTERSTUFFING BOX/SHAFTRAW WATER FEEDMUFFLERENGINECOOLANTRESV.BATTERYDCPANELCONTROLSSHIFTTHROTTLEPANEL HARNESSPLANHOSES TOWATER HTR.STARTING SYSTEMBATT SWELECTRICALSYSTEMSTARTING BATTERYHOUSE BATTERYOPT. INVERTER12V SYSTEM110V SYSTEMSHORE POWERTOFUELTANKCONTROLCABLES TOPEDESTALFUEL RETURNFUEL FEED W/FILTERINSTUMT. PANEL WIRE HARNESSSHIFT CABLEENGINE STOP CABLE(FLEX SHUT OFF)THROTTLE CABLEENGINE ENCLOSURECOOLANTRESV.ENGINEA.C.PANELINV.PANELSHORE PWRTOAPPLIANCESOPT.BATT. CHGR./ INVTR.Fig. 11.1MUFFLERRAW WTR.FEED W/STRAINERBATTERYHEAT EXCHANGEBLEEDER VALVESEE PLAN ABOVE FOR PROP SHAFT & STUFFING BOXELEVATIONHOSES TOWAT.HTR.HULL BOTTOM11.2NOTE: THIS DWG. IS GENERIC SCHEMATIC FORMHOUSE SYSTEM