36e Operator's Manual 2013.pdf - Marlow-Hunter, LLC

36e Operator's Manual 2013.pdf - Marlow-Hunter, LLC

36e Operator's Manual 2013.pdf - Marlow-Hunter, LLC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

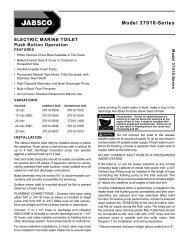

<strong>Hunter</strong> e36 • Maintenanceboat’s bonding system) on the outside of the transom.14.2.10.1 Keel Maintenance for Cast Iron (whereapplicable)The cast iron keel (upper section only on somemodels) was coated with an epoxy primer beforeleaving <strong>Hunter</strong> Marine. You will find that as withmost items, particularly underwater gear, ongoingmaintenance will probably be required during seasonalor routine haulouts.The epoxy primer used on your boats Keel orupper section was manufactured by InternationalMarine Coatings. The product numbers used are asFollows:Intergrade 269 Epoxy Primer / Tie CoatingColor / EGZ088 – Red BaseConverter / Curing Agent – EGA 089The above products should be applied accordingto the manufactures printed instructions. For moreinformation you may wish to visit their website athttp://www.yachtpaint.com/usa/ or call 800-468-7589by email to Interluxtechnicalservice@internationalpaint.com.Compatibility of product should be investigated ifother brands or types of Epoxy Coatings are preferredby the boat owner or repair facility.14.2.11 FlexiteekListed below are specific instructions for the maintenanceof your Flexiteek. These instructions are direct from thevendor Control Masters.“Your Flexiteek deck is low maintenance and never needsoiling or special sealants. The on board shoe trafficamount will determine how often you will need to rinse orwash your deck. Flexiteek is stain resistant. Most spillswill brush away with soap and water. (Simple Green isone recommended soap brand.) Should a chemical stainbe left to dry out and soap is not enough, then removeit with a piece of 60-grit sandpaper on a sanding blockgoing along the grain pattern. Your deck panels are nota laminate so a light sanding will not harm the surface.No sealant is ever necessary after sanding either. Blendtoned by lightly sanding the surrounding area parallel tothe caulk lines by applying strokes to the surface in onedirection.Flexiteek may be pressure cleaned. Pressure cleaning iseffective, if necessary, to lighten the tone of a deck shouldyou notice any shading has occurred which may takeplace in regions close to the Equator. You may chooseto sand with 60-grit sandpaper on a sanding block asdescribed to restore to the original tone. Only apply lightpressure when sanding for the best results. Unlike realteak, only minimal sanding is ever needed on Flexiteek.Use boat shoes or no shoes at all as you normally doalready. Black sole shoes permitted on deck may scuffany deck surface. The unique non-skid characteristic ofthe deck surface will grip shoes and feet when wet.Do Not place hot metals on Flexiteek decks. Treat yourFlexiteek deck with the care you would give a teak deck(except oiling)!Acetone must never be used to clean this material surface.Do Not try to mop the surface. Use a bristled brush, rinsewith a hose and leave it to air dry. Power sanders willdistort the teak wood appearance.Do Not oil, bleach, varnish, paint or lacquer your Flexiteekas this will reduce the non-slip characteristic of the material.If you wash your walls with bleach, then first spraythe Flexiteek deck with water in order to dilute bleach thatwill run on the deck surface. After walls are washed, resprayboth the wall and Flexiteek in order to rinse awayany bleach that has pooled on top of the Flexiteek. Apatch can repair any portion of the deck that becomesdamaged. Contact your regional distributor listed on ourwebpage: www.flexiteek.com.”14.3 InteriorYou can usually clean the surfaces of these componentswith a mild cleaner such as Fantastic. Avoid using harshor abrasive cleaners. Use approved marine sanitarytreatment chemicals to control the odor in the toilet andholding tank.14.3.2 WallsThe wood used in your boat is treated at the factory witha multi-coat finish process. To maintain the finish, use agood grade of furniture polish.14.3.4 BilgesThe bilges are finished with a high quality gelcoat which14.5