EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

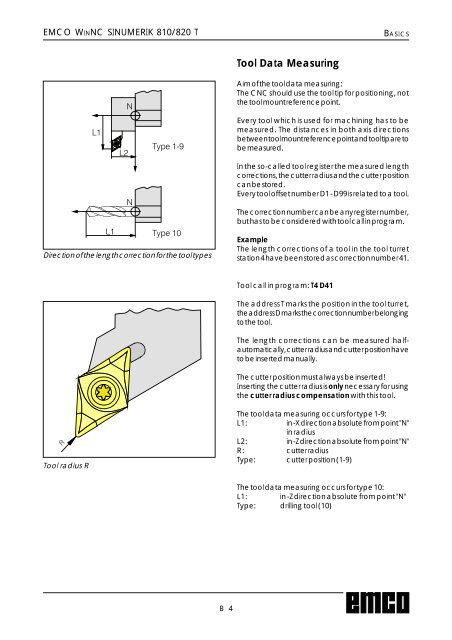

<strong>EMCO</strong> WINNC <strong>SINUMERIK</strong> <strong>810</strong>/<strong>820</strong> TBASICSTool Data Measuring1/7\SH/1/ 7\SHDirection of the length correction for the tool typesAim of the tool data measuring:The CNC should use the tool tip for positioning, notthe tool mount reference point.Every tool which is used for machining has to bemeasured. The distances in both axis directionsbetween tool mount reference point and tool tip are tobe measured.In the so-called tool register the measured lengthcorrections, the cutter radius and the cutter positioncan be stored.Every tool offset number D1 - D99 is related to a tool.The correction number can be any register number,but has to be considered with tool call in program.ExampleThe length corrections of a tool in the tool turretstation 4 have been stored as correction number 41.Tool call in program: T4 D41The address T marks the position in the tool turret,the address D marks the correction number belongingto the tool.The length corrections can be measured halfautomatically,cutter radius and cutter position haveto be inserted manually.The cutter position must always be inserted!Inserting the cutter radius is only necessary for usingthe cutter radius compensation with this tool.5Tool radius RThe tool data measuring occurs for type 1-9:L1: in -X direction absolute from point "N"in radiusL2: in -Z direction absolute from point "N"R :cutter radiusType: cutter position (1-9)The tool data measuring occurs for type 10:L1: in -Z direction absolute from point "N"Type: drilling tool (10)B 4