EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

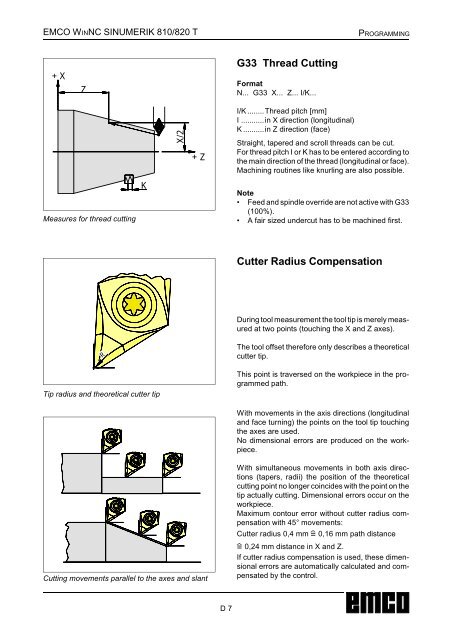

<strong>EMCO</strong> WINNC <strong>SINUMERIK</strong> <strong>810</strong>/<strong>820</strong> TPROGRAMMING+XZG33 Thread CuttingFormatN... G33 X... Z... I/K...X/2+ZI/K ........Thread pitch [mm]I ...........in X direction (longitudinal)K ..........in Z direction (face)Straight, tapered and scroll threads can be cut.For thread pitch I or K has to be entered according tothe main direction of the thread (longitudinal or face).Machining routines like knurling are also possible.Measures for thread cuttingKNote• Feed and spindle override are not active with G33(100%).• A fair sized undercut has to be machined first.Cutter Radius CompensationDuring tool measurement the tool tip is merely measuredat two points (touching the X and Z axes).RThe tool offset therefore only describes a theoreticalcutter tip.Tip radius and theoretical cutter tipThis point is traversed on the workpiece in the programmedpath.With movements in the axis directions (longitudinaland face turning) the points on the tool tip touchingthe axes are used.No dimensional errors are produced on the workpiece.Cutting movements parallel to the axes and slantWith simultaneous movements in both axis directions(tapers, radii) the position of the theoreticalcutting point no longer coincides with the point on thetip actually cutting. Dimensional errors occur on theworkpiece.Maximum contour error without cutter radius compensationwith 45° movements:Cutter radius 0,4 mm = 0,16 mm path distance= 0,24 mm distance in X and Z.If cutter radius compensation is used, these dimensionalerrors are automatically calculated and compensatedby the control.D 7