EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

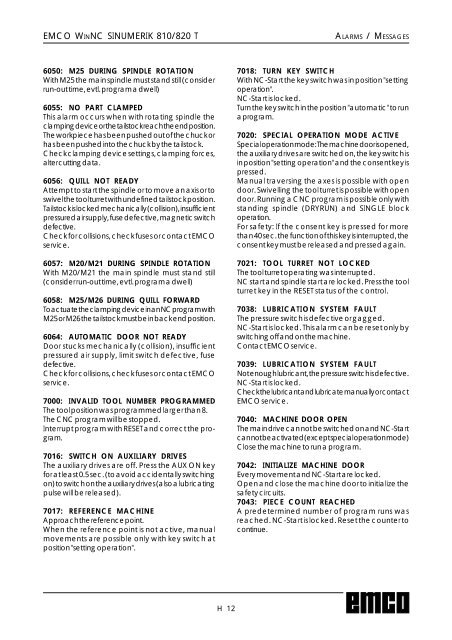

<strong>EMCO</strong> WINNC <strong>SINUMERIK</strong> <strong>810</strong>/<strong>820</strong> TALARMS / MESSAGES6050: M25 DURING SPINDLE ROTATIONWith M25 the main spindle must stand still (considerrun-out time, evtl. program a dwell)6055: NO PART CLAMPEDThis alarm occurs when with rotating spindle theclamping device or the tailstock reach the end position.The workpiece has been pushed out of the chuck orhas been pushed into the chuck by the tailstock.Check clamping device settings, clamping forces,alter cutting data.6056: QUILL NOT READYAttempt to start the spindle or to move an axis or toswivel the tool turret with undefined tailstock position.Tailstock is locked mechanically (collision), insufficientpressured air supply, fuse defective, magnetic switchdefective.Check for collisions, check fuses or contact <strong>EMCO</strong>service.6057: M20/M21 DURING SPINDLE ROTATIONWith M20/M21 the main spindle must stand still(consider run-out time, evtl. program a dwell)6058: M25/M26 DURING QUILL FORWARDTo actuate the clamping device in an NC program withM25 or M26 the tailstock must be in back end position.6064: AUTOMATIC DOOR NOT READYDoor stucks mechanically (collision), insufficientpressured air supply, limit switch defective, fusedefective.Check for collisions, check fuses or contact <strong>EMCO</strong>service.7000: INVALID TOOL NUMBER PROGRAMMEDThe tool position was programmed larger than 8.The CNC program will be stopped.Interrupt program with RESET and correct the program.7016: SWITCH ON AUXILIARY DRIVESThe auxiliary drives are off. Press the AUX ON keyfor at least 0.5 sec. (to avoid accidentally switchingon) to switch on the auxiliary drives (also a lubricatingpulse will be released).7017: REFERENCE MACHINEApproach the reference point.When the reference point is not active, manualmovements are possible only with key switch atposition "setting operation".7018: TURN KEY SWITCHWith NC-Start the key switch was in position "settingoperation".NC-Start is locked.Turn the key switch in the position "automatic" to runa program.7020: SPECIAL OPERATION MODE ACTIVESpecial operation mode: The machine door is opened,the auxiliary drives are switched on, the key switch isin position "setting operation" and the consent key ispressed.Manual traversing the axes is possible with opendoor. Swivelling the tool turret is possible with opendoor. Running a CNC program is possible only withstanding spindle (DRYRUN) and SINGLE blockoperation.For safety: If the consent key is pressed for morethan 40 sec. the function of this key is interrupted, theconsent key must be released and pressed again.7021: TOOL TURRET NOT LOCKEDThe tool turret operating was interrupted.NC start and spindle start are locked. Press the toolturret key in the RESET status of the control.7038: LUBRICATION SYSTEM FAULTThe pressure switch is defective or gagged.NC-Start is locked. This alarm can be reset only byswitching off and on the machine.Contact <strong>EMCO</strong> service.7039: LUBRICATION SYSTEM FAULTNot enough lubricant, the pressure switch is defective.NC-Start is locked.Check the lubricant and lubricate manually or contact<strong>EMCO</strong> service.7040: MACHINE DOOR OPENThe main drive can not be switched on and NC-Startcan not be activated (except special operation mode)Close the machine to run a program.7042: INITIALIZE MACHINE DOOREvery movement and NC-Start are locked.Open and close the machine door to initialize thesafety circuits.7043: PIECE COUNT REACHEDA predetermined number of program runs wasreached. NC-Start is locked. Reset the counter tocontinue.H 12