EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

EMCO WinNC SINUMERIK 810/820 T Software Description ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

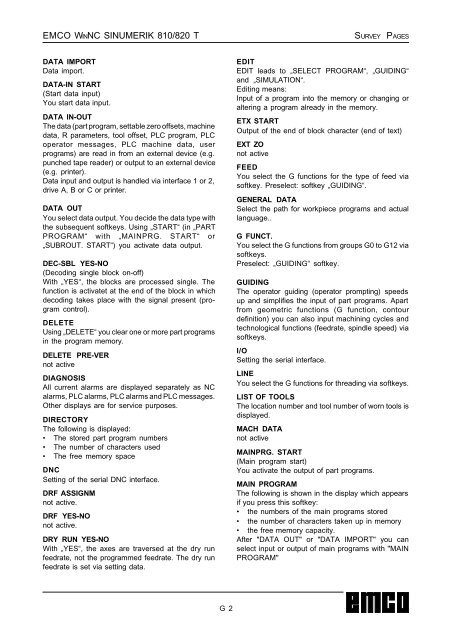

<strong>EMCO</strong> WINNC <strong>SINUMERIK</strong> <strong>810</strong>/<strong>820</strong> TSURVEY PAGESDATA IMPORTData import.DATA-IN START(Start data input)You start data input.DATA IN-OUTThe data (part program, settable zero offsets, machinedata, R parameters, tool offset, PLC program, PLCoperator messages, PLC machine data, userprograms) are read in from an external device (e.g.punched tape reader) or output to an external device(e.g. printer).Data input and output is handled via interface 1 or 2,drive A, B or C or printer.DATA OUTYou select data output. You decide the data type withthe subsequent softkeys. Using „START“ (in „PARTPROGRAM“ with „MAINPRG. START“ or„SUBROUT. START“) you activate data output.DEC-SBL YES-NO(Decoding single block on-off)With „YES“, the blocks are processed single. Thefunction is activatet at the end of the block in whichdecoding takes place with the signal present (programcontrol).DELETEUsing „DELETE“ you clear one or more part programsin the program memory.DELETE PRE-VERnot activeDIAGNOSISAll current alarms are displayed separately as NCalarms, PLC alarms, PLC alarms and PLC messages.Other displays are for service purposes.DIRECTORYThe following is displayed:• The stored part program numbers• The number of characters used• The free memory spaceDNCSetting of the serial DNC interface.DRF ASSIGNMnot active.DRF YES-NOnot active.DRY RUN YES-NOWith „YES“, the axes are traversed at the dry runfeedrate, not the programmed feedrate. The dry runfeedrate is set via setting data.EDITEDIT leads to „SELECT PROGRAM“, „GUIDING“and „SIMULATION“.Editing means:Input of a program into the memory or changing oraltering a program already in the memory.ETX STARTOutput of the end of block character (end of text)EXT ZOnot activeFEEDYou select the G functions for the type of feed viasoftkey. Preselect: softkey „GUIDING“.GENERAL DATASelect the path for workpiece programs and actuallanguage..G FUNCT.You select the G functions from groups G0 to G12 viasoftkeys.Preselect: „GUIDING“ softkey.GUIDINGThe operator guiding (operator prompting) speedsup and simplifies the input of part programs. Apartfrom geometric functions (G function, contourdefinition) you can also input machining cycles andtechnological functions (feedrate, spindle speed) viasoftkeys.I/OSetting the serial interface.LINEYou select the G functions for threading via softkeys.LIST OF TOOLSThe location number and tool number of worn tools isdisplayed.MACH DATAnot activeMAINPRG. START(Main program start)You activate the output of part programs.MAIN PROGRAMThe following is shown in the display which appearsif you press this softkey:• the numbers of the main programs stored• the number of characters taken up in memory• the free memory capacity.After "DATA OUT" or "DATA IMPORT" you canselect input or output of main programs with "MAINPROGRAM"G 2