General Design Principles for DuPont Engineering Polymers - Module

General Design Principles for DuPont Engineering Polymers - Module

General Design Principles for DuPont Engineering Polymers - Module

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Rib <strong>Design</strong><br />

As discussed earlier, the use of ribs to improve rigidity<br />

and reduce weight is acceptable only when such<br />

product improvement is essential. This restriction of<br />

course is due to the possible surface and warpage<br />

problems that can be caused by ribbing. Once the need<br />

<strong>for</strong> ribs has been established, they should not be used<br />

arbitrarily, but rather to provide a specified improvement<br />

in rigidity, weight reduction or both. Two types<br />

of ribbing are considered here: cross-ribbing and<br />

unidirectional. In both cases, graphical plots are<br />

presented to simplify problem solution.<br />

Guidelines <strong>for</strong> selecting rib proportions are shown in<br />

Figure 4.07. Height of the rib should be determined<br />

by structural design, and in some cases could be<br />

limited by molding conditions. Fillet radius at base of<br />

rib should be 1 ⁄ 2 the rib thickness.<br />

Figure 4.07<br />

Cross-Ribbing<br />

Most housings—tape cassettes, pressure containers,<br />

meter shrouds, and just plain boxes—have one<br />

functional requirement in common: the need <strong>for</strong><br />

rigidity when a load is applied. Since rigidity is<br />

directly proportional to the moment of inertia of the<br />

housing cross section, it is physically simple (though<br />

sometimes mathematically complex) to replace a<br />

constant wall section part with a ribbed structure with<br />

the same rigidity but less weight. To simplify such<br />

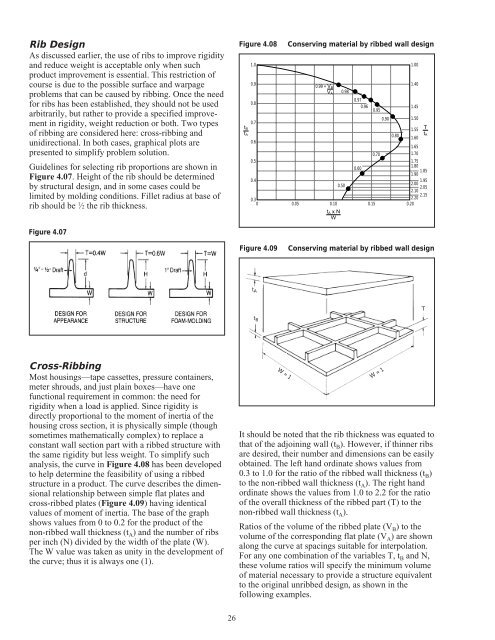

analysis, the curve in Figure 4.08 has been developed<br />

to help determine the feasibility of using a ribbed<br />

structure in a product. The curve describes the dimensional<br />

relationship between simple flat plates and<br />

cross-ribbed plates (Figure 4.09) having identical<br />

values of moment of inertia. The base of the graph<br />

shows values from 0 to 0.2 <strong>for</strong> the product of the<br />

non-ribbed wall thickness (t A) and the number of ribs<br />

per inch (N) divided by the width of the plate (W).<br />

The W value was taken as unity in the development of<br />

the curve; thus it is always one (1).<br />

26<br />

Figure 4.08 Conserving material by ribbed wall design<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

tB<br />

tA<br />

0.6<br />

T<br />

tA<br />

0.5<br />

0.4<br />

0.3<br />

0 0.05<br />

0.10<br />

0.15<br />

2.20<br />

0.20<br />

2.15<br />

2.10 2.05<br />

2.00 1.95<br />

0.99 = VB<br />

VA 0.98<br />

1.40<br />

0.97<br />

0.96<br />

0.95<br />

1.45<br />

0.90<br />

0.80<br />

1.50<br />

1.55<br />

1.60<br />

1.65<br />

0.70<br />

1.70<br />

1.75<br />

0.60<br />

1.80<br />

1.85<br />

1.90<br />

0.50<br />

tA x N<br />

W<br />

Figure 4.09 Conserving material by ribbed wall design<br />

tA<br />

t B<br />

W = 1<br />

W = 1<br />

It should be noted that the rib thickness was equated to<br />

that of the adjoining wall (tB). However, if thinner ribs<br />

are desired, their number and dimensions can be easily<br />

obtained. The left hand ordinate shows values from<br />

0.3 to 1.0 <strong>for</strong> the ratio of the ribbed wall thickness (tB) to the non-ribbed wall thickness (tA). The right hand<br />

ordinate shows the values from 1.0 to 2.2 <strong>for</strong> the ratio<br />

of the overall thickness of the ribbed part (T) to the<br />

non-ribbed wall thickness (tA). Ratios of the volume of the ribbed plate (VB) to the<br />

volume of the corresponding flat plate (VA) are shown<br />

along the curve at spacings suitable <strong>for</strong> interpolation.<br />

For any one combination of the variables T, tB and N,<br />

these volume ratios will specify the minimum volume<br />

of material necessary to provide a structure equivalent<br />

to the original unribbed design, as shown in the<br />

following examples.<br />

1.00<br />

T