General Design Principles for DuPont Engineering Polymers - Module

General Design Principles for DuPont Engineering Polymers - Module

General Design Principles for DuPont Engineering Polymers - Module

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Welding Double Joints<br />

The simultaneous welding of two joints, e.g. in the<br />

carburettor float in Figure 11.33, requires special<br />

processes and greater care. Practical experience has<br />

shown that it is impossible to get good results if the<br />

two halves are gripped and driven by tooth crowns.<br />

Recesses or ribs must always be provided. It is best if<br />

the machine has facilities <strong>for</strong> adjusting the respective<br />

heights of the inner and outer jig faces, so that the<br />

weld pressure can be distributed over both joints as<br />

required.<br />

In these cases the moment of inertia and the welding<br />

pressure must be calculated <strong>for</strong> the sum of the surfaces.<br />

The speed, on the other hand, should be chosen<br />

as a function of the smaller diameter.<br />

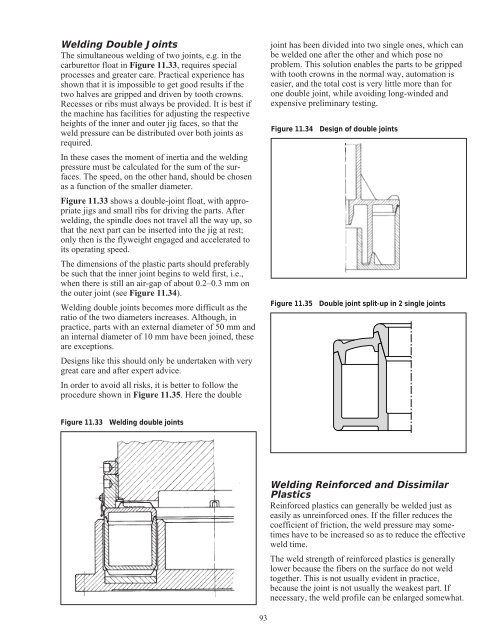

Figure 11.33 shows a double-joint float, with appropriate<br />

jigs and small ribs <strong>for</strong> driving the parts. After<br />

welding, the spindle does not travel all the way up, so<br />

that the next part can be inserted into the jig at rest;<br />

only then is the flyweight engaged and accelerated to<br />

its operating speed.<br />

The dimensions of the plastic parts should preferably<br />

be such that the inner joint begins to weld first, i.e.,<br />

when there is still an air-gap of about 0.2–0.3 mm on<br />

the outer joint (see Figure 11.34).<br />

Welding double joints becomes more difficult as the<br />

ratio of the two diameters increases. Although, in<br />

practice, parts with an external diameter of 50 mm and<br />

an internal diameter of 10 mm have been joined, these<br />

are exceptions.<br />

<strong>Design</strong>s like this should only be undertaken with very<br />

great care and after expert advice.<br />

In order to avoid all risks, it is better to follow the<br />

procedure shown in Figure 11.35. Here the double<br />

Figure 11.33 Welding double joints<br />

93<br />

joint has been divided into two single ones, which can<br />

be welded one after the other and which pose no<br />

problem. This solution enables the parts to be gripped<br />

with tooth crowns in the normal way, automation is<br />

easier, and the total cost is very little more than <strong>for</strong><br />

one double joint, while avoiding long-winded and<br />

expensive preliminary testing.<br />

Figure 11.34 <strong>Design</strong> of double joints<br />

Figure 11.35 Double joint split-up in 2 single joints<br />

Welding Rein<strong>for</strong>ced and Dissimilar<br />

Plastics<br />

Rein<strong>for</strong>ced plastics can generally be welded just as<br />

easily as unrein<strong>for</strong>ced ones. If the filler reduces the<br />

coefficient of friction, the weld pressure may sometimes<br />

have to be increased so as to reduce the effective<br />

weld time.<br />

The weld strength of rein<strong>for</strong>ced plastics is generally<br />

lower because the fibers on the surface do not weld<br />

together. This is not usually evident in practice,<br />

because the joint is not usually the weakest part. If<br />

necessary, the weld profile can be enlarged somewhat.