BIOENERGY FOR EUROPE: WHICH ONES FIT BEST?

BIOENERGY FOR EUROPE: WHICH ONES FIT BEST?

BIOENERGY FOR EUROPE: WHICH ONES FIT BEST?

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

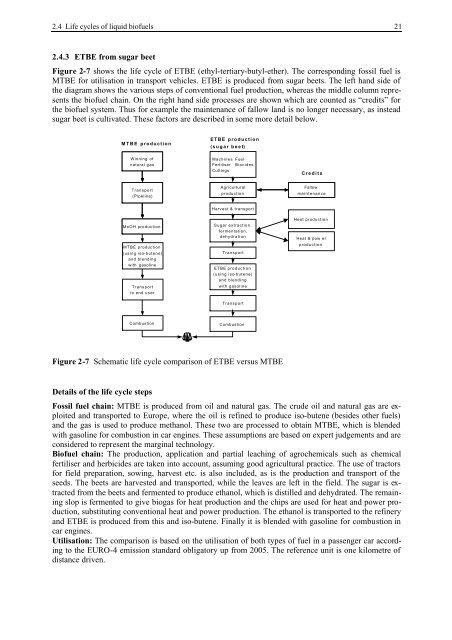

2.4 Life cycles of liquid biofuels 21<br />

2.4.3 ETBE from sugar beet<br />

Figure 2-7 shows the life cycle of ETBE (ethyl-tertiary-butyl-ether). The corresponding fossil fuel is<br />

MTBE for utilisation in transport vehicles. ETBE is produced from sugar beets. The left hand side of<br />

the diagram shows the various steps of conventional fuel production, whereas the middle column represents<br />

the biofuel chain. On the right hand side processes are shown which are counted as “credits” for<br />

the biofuel system. Thus for example the maintenance of fallow land is no longer necessary, as instead<br />

sugar beet is cultivated. These factors are described in some more detail below.<br />

MTBE production<br />

Winning of<br />

natural gas<br />

Transport<br />

(Pipeline)<br />

MeOH production<br />

MTBE production<br />

(using iso-butene)<br />

and blending<br />

with gasoline<br />

Transport<br />

to end user<br />

Combustion<br />

ETBE production<br />

( sugar beet)<br />

Machines Fuel<br />

Fertiliser Biocides<br />

Cuttings<br />

Agricultural<br />

production<br />

Harvest & transport<br />

Sugar extraction,<br />

fermentation,<br />

dehydration<br />

Transport<br />

ETBE production<br />

(using iso-butene)<br />

and blending<br />

with gasoline<br />

Transport<br />

Combustion<br />

Figure 2-7 Schematic life cycle comparison of ETBE versus MTBE<br />

Details of the life cycle steps<br />

Credits<br />

Fallow<br />

maintenance<br />

Heat production<br />

Heat & pow er<br />

production<br />

Fossil fuel chain: MTBE is produced from oil and natural gas. The crude oil and natural gas are exploited<br />

and transported to Europe, where the oil is refined to produce iso-butene (besides other fuels)<br />

and the gas is used to produce methanol. These two are processed to obtain MTBE, which is blended<br />

with gasoline for combustion in car engines. These assumptions are based on expert judgements and are<br />

considered to represent the marginal technology.<br />

Biofuel chain: The production, application and partial leaching of agrochemicals such as chemical<br />

fertiliser and herbicides are taken into account, assuming good agricultural practice. The use of tractors<br />

for field preparation, sowing, harvest etc. is also included, as is the production and transport of the<br />

seeds. The beets are harvested and transported, while the leaves are left in the field. The sugar is extracted<br />

from the beets and fermented to produce ethanol, which is distilled and dehydrated. The remaining<br />

slop is fermented to give biogas for heat production and the chips are used for heat and power production,<br />

substituting conventional heat and power production. The ethanol is transported to the refinery<br />

and ETBE is produced from this and iso-butene. Finally it is blended with gasoline for combustion in<br />

car engines.<br />

Utilisation: The comparison is based on the utilisation of both types of fuel in a passenger car according<br />

to the EURO-4 emission standard obligatory up from 2005. The reference unit is one kilometre of<br />

distance driven.