BIOENERGY FOR EUROPE: WHICH ONES FIT BEST?

BIOENERGY FOR EUROPE: WHICH ONES FIT BEST?

BIOENERGY FOR EUROPE: WHICH ONES FIT BEST?

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

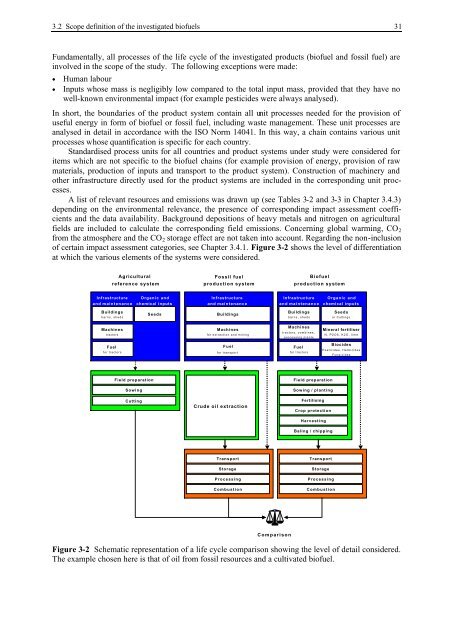

3.2 Scope definition of the investigated biofuels 31<br />

Fundamentally, all processes of the life cycle of the investigated products (biofuel and fossil fuel) are<br />

involved in the scope of the study. The following exceptions were made:<br />

• Human labour<br />

• Inputs whose mass is negligibly low compared to the total input mass, provided that they have no<br />

well-known environmental impact (for example pesticides were always analysed).<br />

In short, the boundaries of the product system contain all unit processes needed for the provision of<br />

useful energy in form of biofuel or fossil fuel, including waste management. These unit processes are<br />

analysed in detail in accordance with the ISO Norm 14041. In this way, a chain contains various unit<br />

processes whose quantification is specific for each country.<br />

Standardised process units for all countries and product systems under study were considered for<br />

items which are not specific to the biofuel chains (for example provision of energy, provision of raw<br />

materials, production of inputs and transport to the product system). Construction of machinery and<br />

other infrastructure directly used for the product systems are included in the corresponding unit processes.<br />

A list of relevant resources and emissions was drawn up (see Tables 3-2 and 3-3 in Chapter 3.4.3)<br />

depending on the environmental relevance, the presence of corresponding impact assessment coefficients<br />

and the data availability. Background depositions of heavy metals and nitrogen on agricultural<br />

fields are included to calculate the corresponding field emissions. Concerning global warming, CO2<br />

from the atmosphere and the CO2 storage effect are not taken into account. Regarding the non-inclusion<br />

of certain impact assessment categories, see Chapter 3.4.1. Figure 3-2 shows the level of differentiation<br />

at which the various elements of the systems were considered.<br />

Infrastructure<br />

and maintenance<br />

Buildings<br />

barns, sheds<br />

Machines<br />

tractors<br />

Fuel<br />

for tractors<br />

Agricultural<br />

reference system<br />

Field preparation<br />

Sowing<br />

Cutting<br />

Organic and<br />

chemical inputs<br />

Seeds<br />

Fossil fuel<br />

production system<br />

Infrastructure<br />

and maintenance<br />

Buildings<br />

Machines<br />

for extraction and mining<br />

Fuel<br />

for transport<br />

Crude oil extraction<br />

Transport<br />

Storage<br />

Processing<br />

Combustion<br />

Comparison<br />

Infrastructure<br />

and maintenance<br />

Buildings<br />

barns, sheds<br />

Machines<br />

tractors, combines,<br />

processing plants<br />

Fuel<br />

for tractors<br />

Biofuel<br />

production system<br />

Field preparation<br />

Sowing / planting<br />

Fertilising<br />

Crop protection<br />

Harvesting<br />

Baling / chipping<br />

Transport<br />

Storage<br />

Processing<br />

Combustion<br />

Organic and<br />

chemical inputs<br />

Seeds<br />

or Cuttings<br />

Mineral fertiliser<br />

N, P2O5, K2O, lime<br />

Biocides<br />

Pesticides, Herbicides<br />

Fungicides<br />

Figure 3-2 Schematic representation of a life cycle comparison showing the level of detail considered.<br />

The example chosen here is that of oil from fossil resources and a cultivated biofuel.