General Information on Track Circuits - RGS Online

General Information on Track Circuits - RGS Online

General Information on Track Circuits - RGS Online

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Withdrawn Document<br />

Unc<strong>on</strong>trolled When Printed<br />

<str<strong>on</strong>g>General</str<strong>on</strong>g> <str<strong>on</strong>g>Informati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>Track</strong> <strong>Circuits</strong><br />

Railway Group Approved Code of Practice<br />

GK/RC0752<br />

Issue Two<br />

Date December 1998<br />

Page E49 of 52<br />

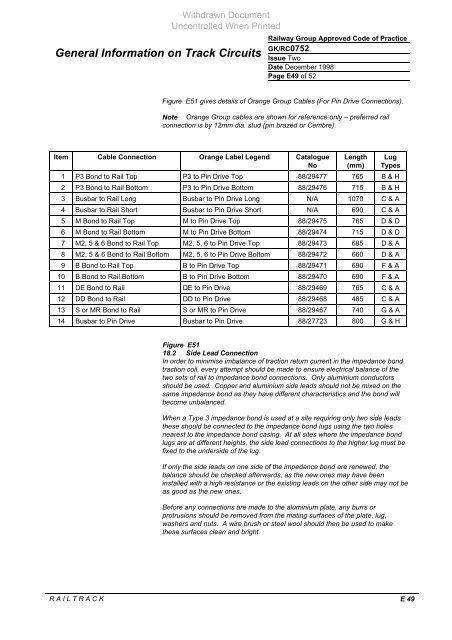

Figure E51 gives details of Orange Group Cables (For Pin Drive C<strong>on</strong>necti<strong>on</strong>s).<br />

Note Orange Group cables are shown for reference <strong>on</strong>ly – preferred rail<br />

c<strong>on</strong>necti<strong>on</strong> is by 12mm dia. stud (pin brazed or Cembre).<br />

Item Cable C<strong>on</strong>necti<strong>on</strong> Orange Label Legend Catalogue<br />

No<br />

Length<br />

(mm)<br />

Lug<br />

Types<br />

1 P3 B<strong>on</strong>d to Rail Top P3 to Pin Drive Top 88/29477 765 B & H<br />

2 P3 B<strong>on</strong>d to Rail Bottom P3 to Pin Drive Bottom 88/29476 715 B & H<br />

3 Busbar to Rail L<strong>on</strong>g Busbar to Pin Drive L<strong>on</strong>g N/A 1070 C & A<br />

4 Busbar to Rail Short Busbar to Pin Drive Short N/A 690 C & A<br />

5 M B<strong>on</strong>d to Rail Top M to Pin Drive Top 88/29475 765 D & D<br />

6 M B<strong>on</strong>d to Rail Bottom M to Pin Drive Bottom 88/29474 715 D & D<br />

7 M2, 5 & 6 B<strong>on</strong>d to Rail Top M2, 5, 6 to Pin Drive Top 88/29473 685 D & A<br />

8 M2, 5 & 6 B<strong>on</strong>d to Rail Bottom M2, 5, 6 to Pin Drive Bottom 88/29472 660 D & A<br />

9 B B<strong>on</strong>d to Rail Top B to Pin Drive Top 88/29471 690 F & A<br />

10 B B<strong>on</strong>d to Rail Bottom B to Pin Drive Bottom 88/29470 690 F & A<br />

11 DE B<strong>on</strong>d to Rail DE to Pin Drive 88/29469 765 C & A<br />

12 DD B<strong>on</strong>d to Rail DD to Pin Drive 88/29468 485 C & A<br />

13 S or MR B<strong>on</strong>d to Rail S or MR to Pin Drive 88/29467 740 G & A<br />

14 Busbar to Pin Drive Busbar to Pin Drive 88/27723 800 G & H<br />

Figure E51<br />

18.2 Side Lead C<strong>on</strong>necti<strong>on</strong><br />

In order to minimise imbalance of tracti<strong>on</strong> return current in the impedance b<strong>on</strong>d<br />

tracti<strong>on</strong> coil, every attempt should be made to ensure electrical balance of the<br />

two sets of rail to impedance b<strong>on</strong>d c<strong>on</strong>necti<strong>on</strong>s. Only aluminium c<strong>on</strong>ductors<br />

should be used. Copper and aluminium side leads should not be mixed <strong>on</strong> the<br />

same impedance b<strong>on</strong>d as they have different characteristics and the b<strong>on</strong>d will<br />

become unbalanced.<br />

When a Type 3 impedance b<strong>on</strong>d is used at a site requiring <strong>on</strong>ly two side leads<br />

these should be c<strong>on</strong>nected to the impedance b<strong>on</strong>d lugs using the two holes<br />

nearest to the impedance b<strong>on</strong>d casing. At all sites where the impedance b<strong>on</strong>d<br />

lugs are at different heights, the side lead c<strong>on</strong>necti<strong>on</strong>s to the higher lug must be<br />

fixed to the underside of the lug.<br />

If <strong>on</strong>ly the side leads <strong>on</strong> <strong>on</strong>e side of the impedance b<strong>on</strong>d are renewed, the<br />

balance should be checked afterwards, as the new <strong>on</strong>es may have been<br />

installed with a high resistance or the existing leads <strong>on</strong> the other side may not be<br />

as good as the new <strong>on</strong>es.<br />

Before any c<strong>on</strong>necti<strong>on</strong>s are made to the aluminium plate, any burrs or<br />

protrusi<strong>on</strong>s should be removed from the mating surfaces of the plate, lug,<br />

washers and nuts. A wire brush or steel wool should then be used to make<br />

these surfaces clean and bright.<br />

R A I L T R A C K E 49