General Information on Track Circuits - RGS Online

General Information on Track Circuits - RGS Online

General Information on Track Circuits - RGS Online

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Railway Group Approved Code of Practice<br />

GK/RC0752<br />

Issue Two<br />

Date December 1998<br />

Page E50 of 52<br />

Withdrawn Document<br />

Unc<strong>on</strong>trolled When Printed<br />

<str<strong>on</strong>g>General</str<strong>on</strong>g> <str<strong>on</strong>g>Informati<strong>on</strong></str<strong>on</strong>g> <strong>on</strong> <strong>Track</strong> <strong>Circuits</strong><br />

All c<strong>on</strong>tact surfaces should be coated with a uniform layer of jointing paste<br />

(Catalogue No. 7/26200) immediately after cleaning and any surplus cleaned<br />

away after tightening. The paste prevents moisture filling the resultant air<br />

spaces between the dissimilar metal surfaces, preventing corrosi<strong>on</strong> which occurs<br />

very rapidly, particularly when aluminium is exposed to air or moisture.<br />

Where screw and nut c<strong>on</strong>necti<strong>on</strong>s are made to aluminium plate, eg. the<br />

aluminium busbar or P3 impedance b<strong>on</strong>d lug plate, it is essential that<br />

mechanical c<strong>on</strong>necti<strong>on</strong>s are not over-tightened. This is because aluminium<br />

displays the property known as ‘‘cold flow” under pressure and if a certain<br />

pressure is exceeded, a flow away from the pressure area occurs and the<br />

c<strong>on</strong>necti<strong>on</strong> becomes loose, resulting in a high resistance c<strong>on</strong>necti<strong>on</strong>.<br />

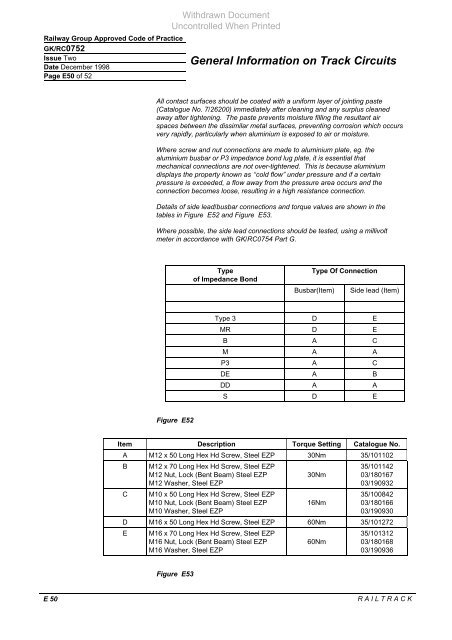

Details of side lead/busbar c<strong>on</strong>necti<strong>on</strong>s and torque values are shown in the<br />

tables in Figure E52 and Figure E53.<br />

Where possible, the side lead c<strong>on</strong>necti<strong>on</strong>s should be tested, using a millivolt<br />

meter in accordance with GK/RC0754 Part G.<br />

Figure E52<br />

Type<br />

of Impedance B<strong>on</strong>d<br />

Type Of C<strong>on</strong>necti<strong>on</strong><br />

Busbar(Item) Side lead (Item)<br />

Type 3 D E<br />

MR D E<br />

B A C<br />

M A A<br />

P3 A C<br />

DE A B<br />

DD A A<br />

S D E<br />

Item Descripti<strong>on</strong> Torque Setting Catalogue No.<br />

A M12 x 50 L<strong>on</strong>g Hex Hd Screw, Steel EZP 30Nm 35/101102<br />

B M12 x 70 L<strong>on</strong>g Hex Hd Screw, Steel EZP<br />

35/101142<br />

M12 Nut, Lock (Bent Beam) Steel EZP<br />

30Nm<br />

03/180167<br />

M12 Washer, Steel EZP<br />

03/190932<br />

C M10 x 50 L<strong>on</strong>g Hex Hd Screw, Steel EZP<br />

35/100842<br />

M10 Nut, Lock (Bent Beam) Steel EZP<br />

16Nm<br />

03/180166<br />

M10 Washer, Steel EZP<br />

03/190930<br />

D M16 x 50 L<strong>on</strong>g Hex Hd Screw, Steel EZP 60Nm 35/101272<br />

E M16 x 70 L<strong>on</strong>g Hex Hd Screw, Steel EZP<br />

35/101312<br />

M16 Nut, Lock (Bent Beam) Steel EZP<br />

60Nm<br />

03/180168<br />

M16 Washer, Steel EZP<br />

03/190936<br />

Figure E53<br />

E 50 R A I L T R A C K