Operation and Maintenance Manual for

Operation and Maintenance Manual for

Operation and Maintenance Manual for

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OPERATING INSTRUCTIONS LC <strong>Manual</strong> 11/02 Rev. 3<br />

H. Set the percent rejection alarm setting to 90%.<br />

I. Check <strong>for</strong> plumbing leaks <strong>and</strong> make appropriate repairs as necessary. All<br />

systems are leak checked at the factory but vibration during transit can cause<br />

new leaks to develop.<br />

J. Once the system is checked out <strong>and</strong> operating correctly, place the controller in<br />

the desired mode. Read the next section on initial flushing be<strong>for</strong>e directing<br />

product water to the water storage tank or user system.<br />

3.3 INITIAL FLUSHING OF THE SYSTEM<br />

Since the RO membranes are shipped with sodium bisulfite preservative solution, initial<br />

flushing of the system is required. Be<strong>for</strong>e operating a new system, <strong>and</strong> also after the<br />

replacement of a RO membrane, per<strong>for</strong>m the following steps:<br />

A. Direct the product water to a convenient drain.<br />

B. Ensure a steady feed water supply, turn on the system pump <strong>and</strong> let the system<br />

run <strong>for</strong> four hours. This will flush residual bisulfite solution <strong>and</strong> any particulate<br />

impurities from the membranes, housings <strong>and</strong> plumbing of the system.<br />

C. Product quality will increase slowly <strong>for</strong> 1 hour. Monitor the inlet quality vs. the<br />

product quality by observing the conductivity meter outputs.<br />

NOTE: The system should have better than 90% rejection within 2 hours as the<br />

membranes equilibrate. If the product quality does not improve, refer to<br />

section 5.0 Troubleshooting.<br />

D. After flushing product to drain <strong>for</strong> a minimum four hours, turn off the system <strong>and</strong><br />

reconnect the product line. The system is now ready to be put into a normal<br />

operating mode. Refer to the Product Description/Equipment Specifications in<br />

the Appendix <strong>for</strong> design flowrates <strong>and</strong> pressures.<br />

3.4 NORMAL OPERATIONS<br />

The following procedure is <strong>for</strong> operating a USFilter Reverse Osmosis System that has<br />

been installed <strong>and</strong> initial flushing has been completed. Refer to the MC10 Controller<br />

manual in the Appendix <strong>for</strong> detailed instructions.<br />

Use this section <strong>for</strong> daily startup or to restart the system after a short-term shutdown.<br />

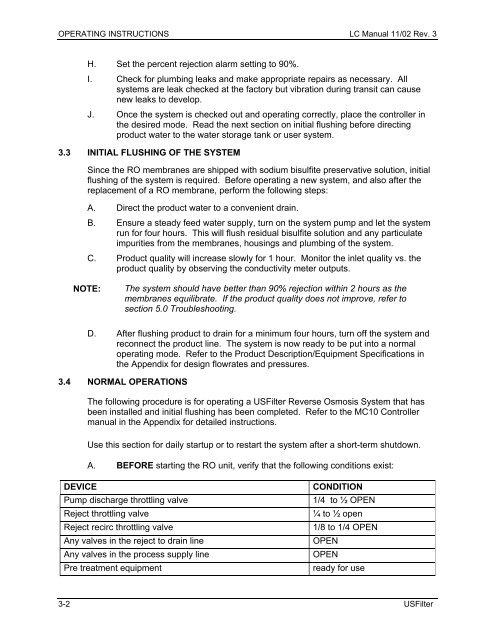

A. BEFORE starting the RO unit, verify that the following conditions exist:<br />

DEVICE CONDITION<br />

Pump discharge throttling valve 1/4 to ½ OPEN<br />

Reject throttling valve ¼ to ½ open<br />

Reject recirc throttling valve 1/8 to 1/4 OPEN<br />

Any valves in the reject to drain line OPEN<br />

Any valves in the process supply line OPEN<br />

Pre treatment equipment ready <strong>for</strong> use<br />

3-2 USFilter