Operation and Maintenance Manual for

Operation and Maintenance Manual for

Operation and Maintenance Manual for

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Calibration 4<br />

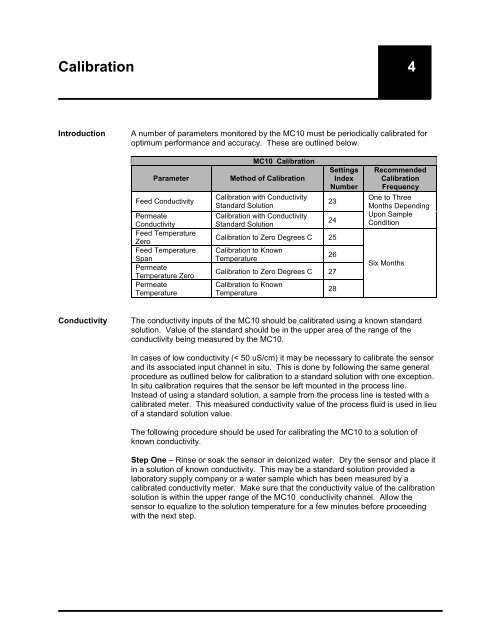

Introduction A number of parameters monitored by the MC10 must be periodically calibrated <strong>for</strong><br />

optimum per<strong>for</strong>mance <strong>and</strong> accuracy. These are outlined below.<br />

MC10 Calibration<br />

Parameter Method of Calibration<br />

Feed Conductivity<br />

Permeate<br />

Conductivity<br />

Feed Temperature<br />

Zero<br />

Feed Temperature<br />

Span<br />

Permeate<br />

Temperature Zero<br />

Permeate<br />

Temperature<br />

Calibration with Conductivity<br />

St<strong>and</strong>ard Solution<br />

Calibration with Conductivity<br />

St<strong>and</strong>ard Solution<br />

Settings<br />

Index<br />

Number<br />

23<br />

24<br />

Calibration to Zero Degrees C 25<br />

Calibration to Known<br />

Temperature<br />

26<br />

Calibration to Zero Degrees C 27<br />

Calibration to Known<br />

Temperature<br />

28<br />

Recommended<br />

Calibration<br />

Frequency<br />

One to Three<br />

Months Depending<br />

Upon Sample<br />

Condition<br />

Six Months<br />

Conductivity The conductivity inputs of the MC10 should be calibrated using a known st<strong>and</strong>ard<br />

solution. Value of the st<strong>and</strong>ard should be in the upper area of the range of the<br />

conductivity being measured by the MC10.<br />

In cases of low conductivity (< 50 uS/cm) it may be necessary to calibrate the sensor<br />

<strong>and</strong> its associated input channel in situ. This is done by following the same general<br />

procedure as outlined below <strong>for</strong> calibration to a st<strong>and</strong>ard solution with one exception.<br />

In situ calibration requires that the sensor be left mounted in the process line.<br />

Instead of using a st<strong>and</strong>ard solution, a sample from the process line is tested with a<br />

calibrated meter. This measured conductivity value of the process fluid is used in lieu<br />

of a st<strong>and</strong>ard solution value.<br />

The following procedure should be used <strong>for</strong> calibrating the MC10 to a solution of<br />

known conductivity.<br />

Step One – Rinse or soak the sensor in deionized water. Dry the sensor <strong>and</strong> place it<br />

in a solution of known conductivity. This may be a st<strong>and</strong>ard solution provided a<br />

laboratory supply company or a water sample which has been measured by a<br />

calibrated conductivity meter. Make sure that the conductivity value of the calibration<br />

solution is within the upper range of the MC10 conductivity channel. Allow the<br />

sensor to equalize to the solution temperature <strong>for</strong> a few minutes be<strong>for</strong>e proceeding<br />

with the next step.