2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 5 <strong>Water</strong> Infrastructure<br />

2. Applying external bonded coatings or polyethylene film encasements (unbonded<br />

film)<br />

3. Using a cathodic protection system<br />

See DSG Chapter 6, Cathodic Protection, for detailed discussion of that protection method.<br />

5.6.8.1 Soil Resistivity<br />

Resistivity refers to the resistance of the environment to promote electrical current flow. It is<br />

the inverse unit measurement used to determine conductivity/corrosiveness of the internal or<br />

external environment in contact with the pipe surfaces. By selecting appropriate backfill (soil) or<br />

modifying chemical properties of the water being carried within the pipe, resistivity can be<br />

adjusted. When resistivity is adjusted, the corrosion rate on pipe surfaces is reduced. See DSG<br />

Chapter 6, Cathodic Protection, Tables 6-9, 6-10, and 6-11.<br />

For the soil pipe interface, adjusting soil resistivity is usually neither possible nor practical.<br />

Providing select backfill has a short-term effect. Over time, constituents in the soil surrounding<br />

the pipe will degrade the backfill and resistivity will approach that of the surrounding material.<br />

Soil corrosivity is based on resistivity measurements of the soil in the pipeline location. Typically,<br />

several measurements are taken and an average value is determined. Where soils are very near<br />

a classification break point, engineering judgment is required to classify the soil (Table 5-6).<br />

Where resistivity tests in one area vary, greater weight is given to the lower values found.<br />

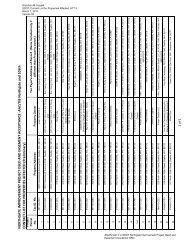

Table 5-6 Corrosion Protection Requirements for <strong>Water</strong> Piping <strong>System</strong>s*<br />

Soil Resistivity (ohm/cm)<br />

0 – 900<br />

901 – 3,000<br />

3,001 – 10,000<br />

10,001 – 50,000<br />

> than 50,000<br />

Soil Corrosivity Classification<br />

Severely-corrosive<br />

Very-corrosive<br />

Moderately-corrosive<br />

Mildly-corrosive<br />

Non-corrosive<br />

*Large projects may have several soil classifications and will need to accommodate each type appropriately.<br />

Table 5-7 shows SPU requirements for water pipelines where coating is dictated by resistivity.<br />

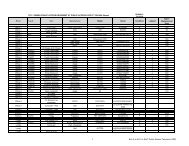

Table 5-7 SPU Corrosion Protection Requirements for Corrosive Soil<br />

Soil Classification<br />

Severely-corrosive<br />

Very-corrosive<br />

Moderately-corrosive<br />

Mildly-corrosive<br />

Non-corrosive<br />

Notes:<br />

Corrosion Protection Requirements<br />

approved bonded coating<br />

joint bonding - #2 AWG<br />

insulating coupling or flange kit @ connections<br />

full dielectric covering on service<br />

lines to meter setter<br />

electrolysis test station<br />

class b bedding (sand)<br />

magnesium anodes @ 18’ intervals (17 lbs high potential magnesium anodes)<br />

[same as above – except anodes are spaced @ 36’ intervals]<br />

[same as above – except anodes are spaced @ 100’ intervals]<br />

- polyethylene encasement – 8 mil<br />

- class b bedding (sand)<br />

- no protection required unless organic or clay materials are encountered<br />

- additional soil tests may be required for proper recommendation<br />

SPU Design Standards and Guidelines<br />

5-37