2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 5 <strong>Water</strong> Infrastructure<br />

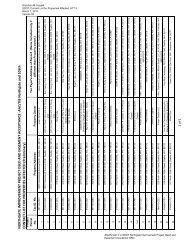

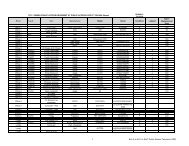

Table 5-9 lists ductile iron pipe coating options. SPU requires a double cement mortar<br />

lining thickness for ductile iron pipe. See AWWA C104 for more detail on cement mortar<br />

linings for ductile iron pipe.<br />

Table 5-9 Ductile Iron Pipe Coating Types for SPU <strong>Water</strong> <strong>System</strong><br />

Coating<br />

Thermoplastic<br />

Powder Coating<br />

Wax Tape system<br />

Polyethylene film<br />

encasement (unbonded<br />

film)<br />

Fusion-Bonded<br />

Epoxy, Polyurethane,<br />

and Tape Coatings<br />

SPU Preference<br />

SPU standard coating for ductile iron (DI) pipe in a corrosive environment. See<br />

Standard Spec 9-30.1(6)C. Can also be used on steel pipe.<br />

When used with appropriate primer and a fiber reinforced outer wrap, this<br />

coating can protect any buried metal surface, bolts, nuts, rods, copper, ductile,<br />

steel, etc.<br />

Common application for corrosion control. Acts as an environmental barrier to<br />

prevent direct contact between pipe and corrosive soils. Not watertight;<br />

groundwater can seep beneath the wrap. Integrity depends on proper installation,<br />

careful handling by contractor, and inspection by owner. Polyethylene encasement<br />

must be per Standard Spec 9-30.1(6) D. SPU has limited success using this<br />

product.<br />

Can be considered as an alternative coating system. Manufacturer has been<br />

unwilling to apply bonded coating at factory. Design engineer should recognize<br />

potential invalidation of pipe warranty if this is field applied.<br />

C. Linings<br />

Lining refers to a product used to protect the inside of a pipe from corrosion and<br />

improve performance and service life. SPU requires a lining for all pipelines. All linings<br />

must be National Sanitation Foundation (NSF) 61-approved.<br />

Ductile iron pipe is typically supplied with a double thickness Portland cement-mortar<br />

lining unless otherwise specified. See Standard Specification 9-30.1(1).<br />

Welded steel pipe is furnished with two primary lining options: cement-mortar or<br />

polyurethane. Cement mortar is a nominal thickness of ¼- to ½-inch. For interior linings,<br />

polyurethane thickness is typically around 20-mils. See Standard Specification 9-30.1(1).<br />

D. Cathodic Protection<br />

Cathodic protection is a means of providing a sacrificial material to become the point<br />

where corrosion occurs.<br />

For a pipeline, cathodic protection provides a separate metal known as a sacrificial<br />

anode to be the point where corrosion occurs. This anode protects the pipeline from<br />

corrosion. By use of either an impressed current rectifier or materials that are<br />

galvanically active (zinc or magnesium), the pipeline becomes the cathode and corrosion<br />

is transferred to the anode.<br />

See DSG Chapter 6, Cathodic Protection, for standards for cathodic protection systems.<br />

E. Environmental Modifications<br />

SPU employs corrosion control techniques such as modifying the pH at its water<br />

treatment plants to reduce internal corrosion of water pipelines. This practice is<br />

controlled by federal regulation under the Safe Drinking <strong>Water</strong> Act and EPA’s Lead and<br />

Copper Rule and is a water quality operational methodology beyond the scope of this<br />

DSG.<br />

SPU Design Standards and Guidelines<br />

5-39