2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

2013 Water System Plan, Volume II - Seattle City Clerk's Office - City ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

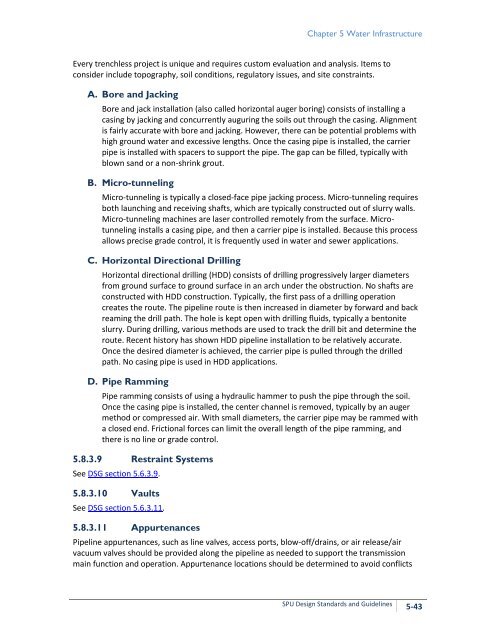

Chapter 5 <strong>Water</strong> Infrastructure<br />

Every trenchless project is unique and requires custom evaluation and analysis. Items to<br />

consider include topography, soil conditions, regulatory issues, and site constraints.<br />

A. Bore and Jacking<br />

Bore and jack installation (also called horizontal auger boring) consists of installing a<br />

casing by jacking and concurrently auguring the soils out through the casing. Alignment<br />

is fairly accurate with bore and jacking. However, there can be potential problems with<br />

high ground water and excessive lengths. Once the casing pipe is installed, the carrier<br />

pipe is installed with spacers to support the pipe. The gap can be filled, typically with<br />

blown sand or a non-shrink grout.<br />

B. Micro-tunneling<br />

Micro-tunneling is typically a closed-face pipe jacking process. Micro-tunneling requires<br />

both launching and receiving shafts, which are typically constructed out of slurry walls.<br />

Micro-tunneling machines are laser controlled remotely from the surface. Microtunneling<br />

installs a casing pipe, and then a carrier pipe is installed. Because this process<br />

allows precise grade control, it is frequently used in water and sewer applications.<br />

C. Horizontal Directional Drilling<br />

Horizontal directional drilling (HDD) consists of drilling progressively larger diameters<br />

from ground surface to ground surface in an arch under the obstruction. No shafts are<br />

constructed with HDD construction. Typically, the first pass of a drilling operation<br />

creates the route. The pipeline route is then increased in diameter by forward and back<br />

reaming the drill path. The hole is kept open with drilling fluids, typically a bentonite<br />

slurry. During drilling, various methods are used to track the drill bit and determine the<br />

route. Recent history has shown HDD pipeline installation to be relatively accurate.<br />

Once the desired diameter is achieved, the carrier pipe is pulled through the drilled<br />

path. No casing pipe is used in HDD applications.<br />

D. Pipe Ramming<br />

Pipe ramming consists of using a hydraulic hammer to push the pipe through the soil.<br />

Once the casing pipe is installed, the center channel is removed, typically by an auger<br />

method or compressed air. With small diameters, the carrier pipe may be rammed with<br />

a closed end. Frictional forces can limit the overall length of the pipe ramming, and<br />

there is no line or grade control.<br />

5.8.3.9 Restraint <strong>System</strong>s<br />

See DSG section 5.6.3.9.<br />

5.8.3.10 Vaults<br />

See DSG section 5.6.3.11.<br />

5.8.3.11 Appurtenances<br />

Pipeline appurtenances, such as line valves, access ports, blow-off/drains, or air release/air<br />

vacuum valves should be provided along the pipeline as needed to support the transmission<br />

main function and operation. Appurtenance locations should be determined to avoid conflicts<br />

SPU Design Standards and Guidelines<br />

5-43