Boxoffice-October.01.1955

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

• •<br />

Do<br />

Third of a New Series<br />

PROJECTOR MAINTENANCE<br />

AND SERVICING GUIDE<br />

3. Care of Cenfury Mechanisms<br />

By WESLEY TROUT<br />

, ^ iKi<br />

V inemaScope<br />

AND wiDEscREEN presentation<br />

requires<br />

more exacting stand-<br />

^"^^ °^ perfection ret^''<br />

^<br />

-M lating to the projec-<br />

Hh JJH tion of motion pic-<br />

W' ~ '^^^ turos. One can read-<br />

' "^^^^ ily comprehend if the<br />

projected picture is 20<br />

feet wide and then increased<br />

to 40 feet in<br />

Wesley Trout<br />

width, any flaw in the<br />

projected picture will be immediately<br />

noticeable to the eye, particularly any sidesway<br />

or jump in the picture.<br />

Manufacturers of projectors have kept<br />

pace with these requirements: a rocksteady<br />

picture without unnecessary side<br />

motion. This has been accomplished by<br />

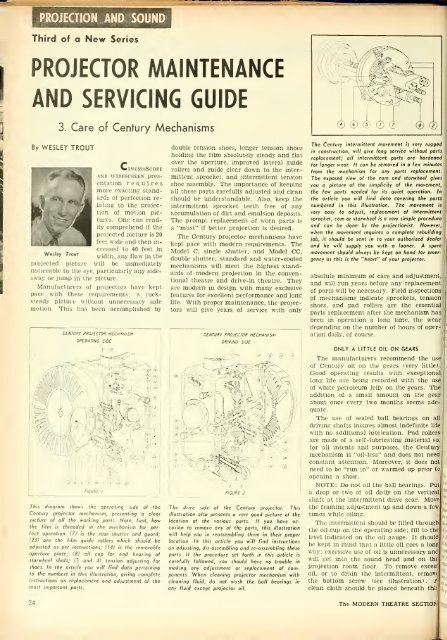

CCKTURY PROJCCTOR MECHANISM<br />

OPCRATINO SIDE<br />

This diagram shows the operating side of the<br />

Century projector mechanism, presenting a clear<br />

picture of all the working parts Note, first, how<br />

the film is threaded in the mechanism for perfeet<br />

operation. (7) is the rear shutter and guard;<br />

C23J are the film guide rollers which should be<br />

adjusted as per instructions; (14) is the removable<br />

aperture plate; (8) oil cup for end bearing of<br />

starwheel shaft; (3 and 4) tension adjusting for<br />

shoes. In the article you will find data pertaining<br />

to the numbers in this illustration, giving complete<br />

instructions on replacement and adjustment of the<br />

most important parts.<br />

double tension shoes, longer tension shoes<br />

holding the film absolutely steady and flat<br />

over the aperture, improved lateral guide<br />

rollers and guide clear down to the intermittent<br />

sprocket, and intermittent tension<br />

shoe assembly. The importance of keeping<br />

all these parts carefully adjusted and clean<br />

should be understandable. Also, keep the<br />

intermittent sprocket teeth free of any<br />

accumulation of dirt and emulsion deposits.<br />

The prompt replacement of worn parts is<br />

a "must" if better projection is desired.<br />

The Century projector mechanisms have<br />

kept pace with modern requirements. The<br />

Model C, single shutter, and Model CC,<br />

double shutter; standard and water-cooled<br />

mechanisms will meet the highest standards<br />

of modern projection in the conventional<br />

theatre and drive-in theatre. They<br />

are modern in design with many exclusive<br />

features for excellent performance and long<br />

life. With proper maintenance, the projectors<br />

will give years of service with only<br />

CEmURY PROJECTOR MECHANISM<br />

DRIVING<br />

riQURE 2<br />

SIOE<br />

The drive side of the Century projector. This<br />

illustration also presents a very good picture of the<br />

location of the various parts. If you have occasion<br />

to remove any of the parts, this illustration<br />

will help you in reassembling them in their proper<br />

location. In this article you will find instructions<br />

on adjusting, disassembling and re-assembling these<br />

parts If the procedure set forth in this article is<br />

carefully followed, you should have no trouble in<br />

making any adjustment or replacement of components.<br />

When cleaning projector mechanism with<br />

cleaning fluid, do not wash the ball bearings in<br />

any fluid except projector oil.<br />

The Century intermittent movement is very rugged<br />

in construction, will give long service without parts<br />

replacement; all intermittent parts are hardened<br />

for longer wear. It can be removed in a few minutes<br />

from the mechanism for any parts replacement.<br />

The exposed view of the cam and starwheel gives<br />

you a picture of the simplicity of the movement,<br />

the few parts needed for its quiet operation. In<br />

the article you will find data covering the parts<br />

numbered in this illustration. The movement is<br />

very easy to adjust, replacement of intermittent<br />

sprocket, cam or starwheel is a very simple procedure<br />

and can be done by the projectionist. However,<br />

when the movement requires a complete rebuilding<br />

job, it should be sent in to your authorized dealer<br />

and he will supply you with a leaner. A spare<br />

movement should always be kept on hand for emergency<br />

as this is the "heart" of your projector.<br />

absolute minimum of care and adjustment,<br />

and will run years before any replacement<br />

of parts will be necessary. Field inspections<br />

of mechanisms indicate sprockets, tension<br />

shoes, and pad rollers are the essential<br />

parts replacement after the mechanism has<br />

been in operation a long time, the wear<br />

depending on the number of hours of operation<br />

daily, of course.<br />

ONLY A LITTLE OIL ON GEARS<br />

The manufacturers recommend the use<br />

a<br />

of Century oil on the gears ivery little).<br />

Good operating results with exceptional<br />

long life are being recorded with the use<br />

of white petroleum jelly on the gears. The<br />

addition of a small amount on the gear<br />

about once every two months seems adequate.<br />

The use of sealed ball bearings on all<br />

driving shafts insures almost indefinite life<br />

with no additional lubrication. Pad rollers<br />

are made of a self-lubricating material so,<br />

for all intents and purposes, the Century<br />

mechanism is "oil-less" and does not need<br />

constant attention. Moreover, it does not<br />

need to be "run in" or warmed up prior to<br />

opening a show.<br />

NOTE : not oil the ball bearings. Put<br />

drop or two of oil daily on the vertical J"<br />

shaft at the intermittent drive gear. Move<br />

III<br />

the framing adjustment up and down a few,<br />

times while oiling.<br />

The intermittent should be filled throughiw<br />

the oil cup on the operating side; fill to the ka<br />

level indicated on the oil gauge. It should<br />

be kept in mind that a little oil goes a long<br />

way; excessive use of oil is unnecessary and<br />

will get into the sound head and on thf<br />

projection room floor. To remove exces:<br />

oil, or to drain the intermittent, rcmovf<br />

the bottom screw (see illustration). /<br />

clean cloth should be placed beneath thi:<br />

I*<br />

24<br />

The MODERN THEATRE SECTIO^