Boxoffice-October.01.1955

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

screw to catch the oil and prevent it from<br />

running down into the sound reproducer<br />

When replacing the druui screw be sure the<br />

steel, fiber and copper washers are placed<br />

In that order on the screw to prevent any<br />

oil leakage.<br />

Caution—Oil should not be added to the<br />

intermittent while the projector is in operation—except<br />

in an extreme emergency.<br />

The intermittent cam acts as a splash distributor<br />

supplying fresh oil constantly to<br />

the cam. starwheel and bearings. Therefore,<br />

there may be no indication of oil level<br />

showing on the gauge while the projector is<br />

operating. The intermittent movement case<br />

should be kept clean and free of any dirt<br />

accumulation.<br />

WEEKLY CHECK OF<br />

OIL<br />

Once a week the oil level should be<br />

checked in the inter/nitterit movement.<br />

Briefly, the Century projection mechanism<br />

has only five rotating shafts and nine<br />

gears, plus the intermittent movement. The<br />

reader will readily understand this means<br />

ease of operation, quieter running and<br />

longer life. The driving shafts are rotated<br />

in sealed-for-life ball bearings which do<br />

not require any special lubricating attention<br />

t<br />

don't oil the ball bearingsK<br />

The upper and lower film sprockets are<br />

hardened and ground to perfect concentricity<br />

and manufactured to approved<br />

standard and diameter. Likewise, the intermittent<br />

parts are hardened for long wear.<br />

The film trap and gate are mechanically<br />

turdy, and all the wearing parts are<br />

lardened and made of the finest steel to<br />

^arantee smooth film travel. The film<br />

rap shoes, studio guides, and the lateral<br />

;uide roller assembly, are designed to guide<br />

he film correctly and insure against side-<br />

Modern Projectors Are Unit-Constructed<br />

To Make for Easier Maintenance<br />

The trend, the past several years, in<br />

modern projector coiustrtiction is to<br />

build all the major components in<br />

units, thereby making removal for inspection,<br />

cleaning and replacement of<br />

parts easy and toithout hatying to disassemble<br />

the entire mechanism to replace<br />

one particular part. To provide for<br />

accurate alignment of all the units,<br />

doivel pins arc provided and the part has<br />

to go back into place correctly: this<br />

method insures all the gears tvill be In<br />

perfect alignmejit, and no mistakes can<br />

be made in reassembling any of the<br />

components.<br />

Intermittent movement parts are all<br />

hardened steel parts, ground to exacting<br />

tolerances, thus making flatuless operation.<br />

The sprockets are hardened for<br />

longer loear. thereby practically eliminating<br />

under-cutting of sprocket teeth.<br />

Bear in mind, however, in time all<br />

sway. The assembly can be quickly removed<br />

for thorough cleaning.<br />

The film gate pad spring adjusting nuts<br />

can be positioned to provide the proper pad<br />

tension for new as well as old film. Opening<br />

and closing the film gate is accomplished<br />

by the large gate knob device<br />

mounted in the lens holder casting.<br />

The shutter shaft and vertical shaft, including<br />

their respective gears, collars, bearings,<br />

are removable from the mechanism<br />

as a complete unit, thereby making replacement<br />

of various parts an easy job.<br />

The two shutters, though revolving In<br />

opposite directions, are scientifically interlocked<br />

to project picture free from any<br />

travel ghost, once properly set. The use<br />

sprockrt.s, due In iveartng of the constant<br />

pulling down of the film, tvill become<br />

under-cut and should t>e immedtatcly<br />

replaced tn order to avoid unnecessary<br />

film damage.<br />

In this series of articles on projector<br />

maintenance, toe have pointed out the<br />

absolute necessity of taking the units<br />

out and cleaning tiyith either kerosene<br />

or solvent, it'ith a smalt amount of projector<br />

oil mixed in the solvent: we do<br />

strongly favor the kerosene. After scrubbing<br />

the parts tolth a stiff -bristle brush,<br />

rinse them clean and dry with a Untless<br />

cloth.<br />

Modern projectors egulpped ntth ball<br />

bearings—Do not clean the ball heanno^<br />

with kerosene. Projector oil may be<br />

used for cleaning these bearings, but do<br />

not soak the ball bearings in oil. Gears,<br />

brackets, etc.. should be cleaned in the<br />

above cleaning fluid only— W. T.<br />

of rear shutter reduces the heat on the<br />

film: however, for very high amperages.<br />

Century has engineered and designed<br />

water-cooled mechanisms.<br />

To more fully acquaint you with operation<br />

and general maintenance, we pre.sent.<br />

in this article, important Instructions on<br />

servicing the Centur>' mechanisms; the<br />

careful reading of these maintenance tips<br />

should result in better projection and<br />

Continued on following<br />

page<br />

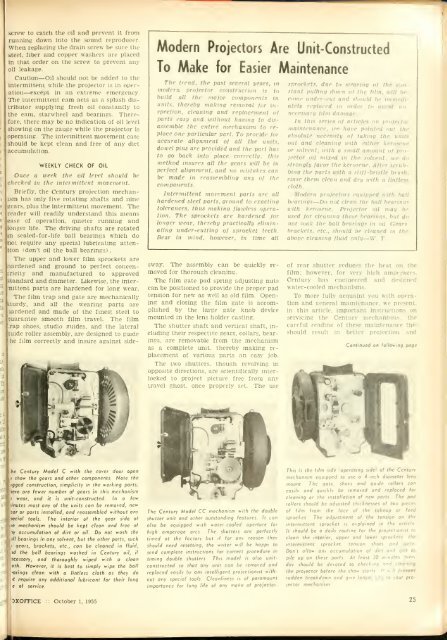

he Century Model C with the cover door open<br />

> show the geon and other components Note the<br />

igged construction, simplicity in the working parts;<br />

iere ore fewer number of gears in this mechanism<br />

> wear, and it is unit-constructed. In a few<br />

•inutes most any of the units can be removed, new<br />

tar or ports installed, and reassembled without any<br />

,.] tecial tools The interior of the gear side of<br />

mechanism should be kept clean and free o/<br />

ly accumulation of dirt or oil. Do not wash the<br />

ill bearings in any solvent, but the other parts, such<br />

I gears, brackets, etc , can be cleaned in fluid,<br />

»rf the ball bearings washed in Century oil, if<br />

scessary, and thoroughly wiped with a clean<br />

eth. However, it is best to simply wipe the ball<br />

ril^tarings clean with a lintless cloth as they do<br />

It require any additional lubricant for their long<br />

• of seryice.<br />

The Century Model CC mechanism with the double<br />

shutter unit and other outstanding features It can<br />

also be equipped with water cooled aperture for<br />

high amperage arcs The shutters are perfectly<br />

timed at the factory but if for any reason they<br />

should need resetting, the writer will be happy to<br />

send complete instructions for correct procedure in<br />

timing double shutters This model is also unitconstructed<br />

so that any unit can be removed and<br />

replaced easily br any intelligent projectionist without<br />

any special tools Cleanliness is of paramount<br />

importance for long life of any make of projector<br />

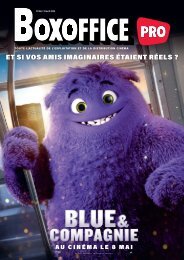

This is the film side (operating side! of the Century<br />

mechanism equipped to use a d-inch diameter lens<br />

mount. The gate, shoes and guide rollers con<br />

easily and quickly be removed and replaced lor<br />

cleaning or the installation of new ports. The pod<br />

rollers should be adjusted thicknesses of two piecet<br />

of film from the face of the takeup or feed<br />

sprocket The adjustment of the tension on the<br />

intermittent sprocket is explained in the article<br />

It ihould be o daily routine for the projectionist to<br />

clean the interior, upper and lower sprockets, the<br />

intermittent sprocket, tension shoes and gate<br />

Don't allow any occumulotlon of dirt and grit to<br />

pile up on these parts At least 30 minutes every<br />

day should be devoted to checking and cleaning<br />

the projector before the show starts. It will prevent<br />

tudden breakdown and give longer lilt to your prolector<br />

mechanism.<br />

JXOFTICE October 1. 1955 25