Burn-in & Test Socket Workshop - BiTS Workshop

Burn-in & Test Socket Workshop - BiTS Workshop

Burn-in & Test Socket Workshop - BiTS Workshop

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Experimental Detail / Analysis<br />

Stage 2 Summary<br />

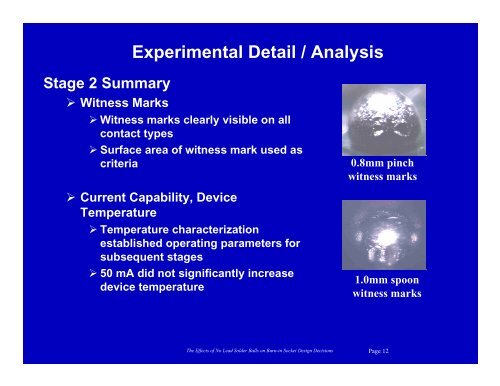

‣ Witness Marks<br />

‣ Witness marks clearly visible on all<br />

contact types<br />

‣ Surface area of witness mark used as<br />

criteria<br />

‣ Current Capability, Device<br />

Temperature<br />

‣ Temperature characterization<br />

established operat<strong>in</strong>g parameters for<br />

subsequent stages<br />

‣ 50 mA did not significantly <strong>in</strong>crease<br />

device temperature<br />

0.8mm p<strong>in</strong>ch<br />

witness marks<br />

1.0mm spoon<br />

witness marks<br />

The Effects of No Lead Solder Balls on <strong>Burn</strong>-<strong>in</strong> <strong>Socket</strong> Design Decisions Page 12