Burn-in & Test Socket Workshop - BiTS Workshop

Burn-in & Test Socket Workshop - BiTS Workshop

Burn-in & Test Socket Workshop - BiTS Workshop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

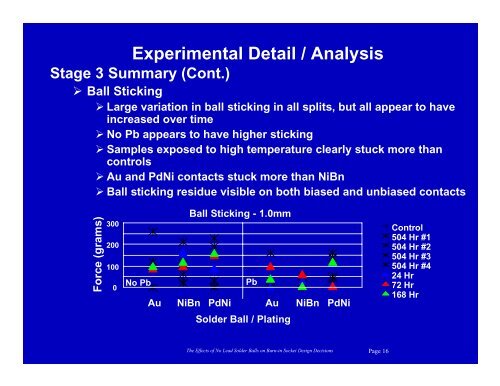

Experimental Detail / Analysis<br />

Stage 3 Summary (Cont.)<br />

‣ Ball Stick<strong>in</strong>g<br />

‣ Large variation <strong>in</strong> ball stick<strong>in</strong>g <strong>in</strong> all splits, but all appear to have<br />

<strong>in</strong>creased over time<br />

‣ No Pb appears to have higher stick<strong>in</strong>g<br />

‣ Samples exposed to high temperature clearly stuck more than<br />

controls<br />

‣ Au and PdNi contacts stuck more than NiBn<br />

‣ Ball stick<strong>in</strong>g residue visible on both biased and unbiased contacts<br />

Force (grams)<br />

300<br />

200<br />

100<br />

0<br />

Ball Stick<strong>in</strong>g - 1.0mm<br />

No Pb<br />

Pb<br />

Au NiBn PdNi Au NiBn PdNi<br />

Control<br />

504 Hr #1<br />

504 Hr #2<br />

504 Hr #3<br />

504 Hr #4<br />

24 Hr<br />

72 Hr<br />

168 Hr<br />

Solder Ball / Plat<strong>in</strong>g<br />

The Effects of No Lead Solder Balls on <strong>Burn</strong>-<strong>in</strong> <strong>Socket</strong> Design Decisions Page 16