Proceedings of the European Summer School of Photovoltaics 4 â 7 ...

Proceedings of the European Summer School of Photovoltaics 4 â 7 ...

Proceedings of the European Summer School of Photovoltaics 4 â 7 ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Analysis <strong>of</strong> selected factors reducing <strong>the</strong> efficiency<br />

<strong>of</strong> silicon solar cells<br />

Agnieszka Stańco, AGH University <strong>of</strong> Science and Technology, Department <strong>of</strong> Electronics, Kraków<br />

Nowadays <strong>the</strong> dominated method <strong>of</strong> receiving energy from natural<br />

sources is photovoltaic (PV). Electric power generation from<br />

sun is realized by solar cells closed in modules. Presently used<br />

materials for <strong>the</strong> cells include mono – crystalline or multi – crystalline<br />

silicon, amorphous silicon and o<strong>the</strong>r compounds based<br />

on exemplary cadmium telluride, copper indium gallium selenide<br />

or even polymers and organic combinations. The main factor describing<br />

PV cells is its efficiency, which is determined by electrical<br />

parameters. The possibility <strong>of</strong> long term using solar systems<br />

requires to fulfill o<strong>the</strong>r conditions which have to limit <strong>the</strong> impact<br />

<strong>of</strong> technology, temperature and lapse <strong>of</strong> time on correct working<br />

<strong>of</strong> cells [1]. The producers state decreasing 90% <strong>of</strong> power solar<br />

systems in about 12 years and 80% in 20 years [2]. The author <strong>of</strong><br />

this work call attention that it is very important for cell to be laminated<br />

after manufacturing processes in order to secure <strong>the</strong>m from<br />

air and humidity. In addition, ambient conditions have also great<br />

influence for working <strong>of</strong> solar cells. It is reported that increasing<br />

temperature in conjunction with solar irradiation also decreases<br />

efficiency <strong>of</strong> PV systems [3].<br />

Experimental<br />

The eight year-old mono and multi-crystalline silicon solar cells<br />

(Cz-Si and mc-Si) <strong>of</strong> area 100 cm 2 were investigated. Morphology<br />

<strong>of</strong> cells surface was studied by using <strong>of</strong> Scanning Microscopy<br />

(NOVA NANO SEM 200, FEI Company). The measurements <strong>of</strong><br />

reflectance R(λ) were carried out by two beam spectrophotometer<br />

UV-VIS-NIR Lambda 19 Perkin Elmer with integration sphere.<br />

Electrical parameters such as: short circuit current I sc<br />

, open<br />

circuit voltage U oc<br />

, fill factor FF and efficiency η were measured<br />

by computer controlled global spectrum sun simulator I-V Curve<br />

Tracer For Solar Cells Qualification. The simulation <strong>of</strong> temperature<br />

impact on efficiency were realized by PC1D Version 5.4<br />

application.<br />

Results and Discussion<br />

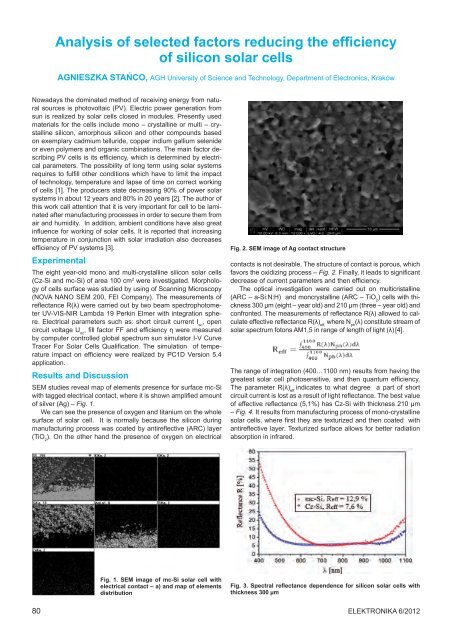

SEM studies reveal map <strong>of</strong> elements presence for surface mc-Si<br />

with tagged electrical contact, where it is shown amplified amount<br />

<strong>of</strong> silver (Ag) – Fig. 1.<br />

We can see <strong>the</strong> presence <strong>of</strong> oxygen and titanium on <strong>the</strong> whole<br />

surface <strong>of</strong> solar cell. It is normally because <strong>the</strong> silicon during<br />

manufacturing process was coated by antireflective (ARC) layer<br />

(TiO 2<br />

). On <strong>the</strong> o<strong>the</strong>r hand <strong>the</strong> presence <strong>of</strong> oxygen on electrical<br />

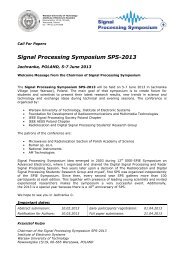

Fig. 2. SEM image <strong>of</strong> Ag contact structure<br />

contacts is not desirable. The structure <strong>of</strong> contact is porous, which<br />

favors <strong>the</strong> oxidizing process – Fig. 2. Finally, it leads to significant<br />

decrease <strong>of</strong> current parameters and <strong>the</strong>n efficiency.<br />

The optical investigation were carried out on multicristalline<br />

(ARC – a-Si:N:H) and moncrystalline (ARC – TiO 2<br />

) cells with thickness<br />

300 µm (eight – year old) and 210 µm (three – year old) and<br />

confronted. The measurements <strong>of</strong> reflectance R(λ) allowed to calculate<br />

effective reflectance R(λ) eff,<br />

where N ph<br />

(λ) constitute stream <strong>of</strong><br />

solar spectrum fotons AM1,5 in range <strong>of</strong> length <strong>of</strong> light (λ) [4].<br />

The range <strong>of</strong> integration (400…1100 nm) results from having <strong>the</strong><br />

greatest solar cell photosensitive, and <strong>the</strong>n quantum efficiency.<br />

The parameter R(λ) eff<br />

indicates to what degree a part <strong>of</strong> short<br />

circuit current is lost as a result <strong>of</strong> light reflectance. The best value<br />

<strong>of</strong> effective reflectance (5,1%) has Cz-Si with thickness 210 µm<br />

– Fig. 4. It results from manufacturing process <strong>of</strong> mono-crystalline<br />

solar cells, where first <strong>the</strong>y are texturized and <strong>the</strong>n coated with<br />

antireflective layer. Texturized surface allows for better radiation<br />

absorption in infrared.<br />

80<br />

Fig. 1. SEM image <strong>of</strong> mc-Si solar cell with<br />

electrical contact – a) and map <strong>of</strong> elements<br />

distribution<br />

Fig. 3. Spectral reflectance dependence for silicon solar cells with<br />

thickness 300 µm<br />

Elektronika 6/2012