Proceedings of the European Summer School of Photovoltaics 4 â 7 ...

Proceedings of the European Summer School of Photovoltaics 4 â 7 ...

Proceedings of the European Summer School of Photovoltaics 4 â 7 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tures in comparison to so far used pastes. Obtained resistance<br />

results for paste firing in 300 and 600 0 C are similar. Resistivity<br />

– firing temperature relationship has shown that already from<br />

250 0 C layers exhibit very good electric conductivity which insignificantly<br />

fluctuates with <strong>the</strong> firing temperature escalation. Results<br />

<strong>of</strong> layer resistance after firing in different conditions have<br />

been shown in Table 1 [4].<br />

The main advantages <strong>of</strong> silver nanopastes is that <strong>the</strong>y do not<br />

contain <strong>the</strong> glaze phase, which impaired electric conduction <strong>of</strong><br />

<strong>the</strong> layer, and <strong>the</strong> possibility <strong>of</strong> firing in lower temperatures. Obtained<br />

results demonstrates that layers made from pastes with<br />

silver nanopowder can be used as ohmic contacts for silicon solar<br />

cells [3].<br />

Experiment<br />

The aim <strong>of</strong> <strong>the</strong> first stage <strong>of</strong> research was to determine electrical<br />

properties <strong>of</strong> contacts made with sputtering method. Such contacts<br />

have been already used to investigate electrical and optical<br />

properties <strong>of</strong> edge-illuminated silicon solar cells and enabled to<br />

acquire repeatable, satisfactory results. Because <strong>of</strong> that <strong>the</strong> sputtering-method-made<br />

contacts have been acknowledged as a good<br />

comparative base for new type <strong>of</strong> silver nanopowder contacts.<br />

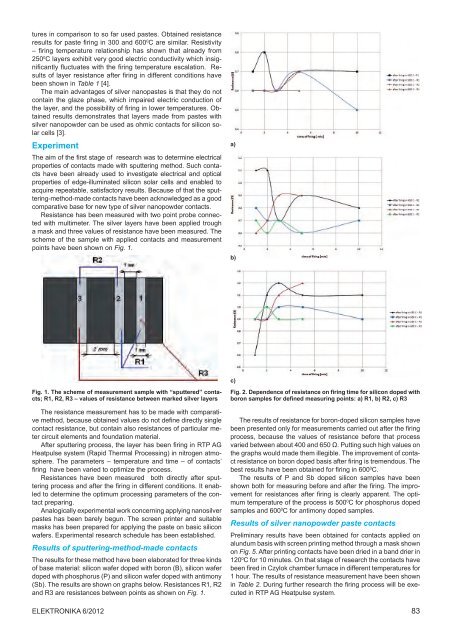

Resistance has been measured with two point probe connected<br />

with multimeter. The silver layers have been applied trough<br />

a mask and three values <strong>of</strong> resistance have been measured. The<br />

scheme <strong>of</strong> <strong>the</strong> sample with applied contacts and measurement<br />

points have been shown on Fig. 1.<br />

a)<br />

b)<br />

c)<br />

Fig. 1. The scheme <strong>of</strong> measurement sample with “sputtered” contacts;<br />

R1, R2, R3 – values <strong>of</strong> resistance between marked silver layers<br />

The resistance measurement has to be made with comparative<br />

method, because obtained values do not define directly single<br />

contact resistance, but contain also resistances <strong>of</strong> particular meter<br />

circuit elements and foundation material.<br />

After sputtering process, <strong>the</strong> layer has been firing in RTP AG<br />

Heatpulse system (Rapid Thermal Processing) in nitrogen atmosphere.<br />

The parameters – temperature and time – <strong>of</strong> contacts’<br />

firing have been varied to optimize <strong>the</strong> process.<br />

Resistances have been measured both directly after sputtering<br />

process and after <strong>the</strong> firing in different conditions. It enabled<br />

to determine <strong>the</strong> optimum processing parameters <strong>of</strong> <strong>the</strong> contact<br />

preparing.<br />

Analogically experimental work concerning applying nanosilver<br />

pastes has been barely begun. The screen printer and suitable<br />

masks has been prepared for applying <strong>the</strong> paste on basic silicon<br />

wafers. Experimental research schedule has been established.<br />

Results <strong>of</strong> sputtering-method-made contacts<br />

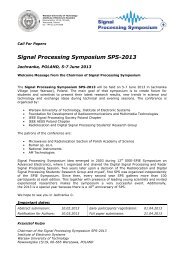

The results for <strong>the</strong>se method have been elaborated for three kinds<br />

<strong>of</strong> base material: silicon wafer doped with boron (B), silicon wafer<br />

doped with phosphorus (P) and silicon wafer doped with antimony<br />

(Sb). The results are shown on graphs below. Resistances R1, R2<br />

and R3 are resistances between points as shown on Fig. 1.<br />

Fig. 2. Dependence <strong>of</strong> resistance on firing time for silicon doped with<br />

boron samples for defined measuring points: a) R1, b) R2, c) R3<br />

The results <strong>of</strong> resistance for boron-doped silicon samples have<br />

been presented only for measurements carried out after <strong>the</strong> firing<br />

process, because <strong>the</strong> values <strong>of</strong> resistance before that process<br />

varied between about 400 and 650 Ω. Putting such high values on<br />

<strong>the</strong> graphs would made <strong>the</strong>m illegible. The improvement <strong>of</strong> contact<br />

resistance on boron doped basis after firing is tremendous. The<br />

best results have been obtained for firing in 600 0 C.<br />

The results <strong>of</strong> P and Sb doped silicon samples have been<br />

shown both for measuring before and after <strong>the</strong> firing. The improvement<br />

for resistances after firing is clearly apparent. The optimum<br />

temperature <strong>of</strong> <strong>the</strong> process is 500 0 C for phosphorus doped<br />

samples and 600 0 C for antimony doped samples.<br />

Results <strong>of</strong> silver nanopowder paste contacts<br />

Preliminary results have been obtained for contacts applied on<br />

alundum basis with screen printing method through a mask shown<br />

on Fig. 5. After printing contacts have been dried in a band drier in<br />

120 0 C for 10 minutes. On that stage <strong>of</strong> research <strong>the</strong> contacts have<br />

been fired in Czylok chamber furnace in different temperatures for<br />

1 hour. The results <strong>of</strong> resistance measurement have been shown<br />

in Table 2. During fur<strong>the</strong>r research <strong>the</strong> firing process will be executed<br />

in RTP AG Heatpulse system.<br />

Elektronika 6/2012 83