CARGO BUSINESS 1-10.indd - ZSSK Cargo

CARGO BUSINESS 1-10.indd - ZSSK Cargo

CARGO BUSINESS 1-10.indd - ZSSK Cargo

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The complex of Eastern Slovak Transhipment Yards (ESTY) is located<br />

on the eastern border of Slovakia and the Schengen area, in the<br />

location of contact of two railway gauges - broad (1520 mm) and<br />

standard (1435 mm). Not accidentally, Čierna nad Tisou is known as<br />

the largest inland port in Slovakia.<br />

In ESTY, 90 percent of raw materials and goods imported by rail<br />

from Eastern Europe and Asia are transhipped. Due to this, the<br />

management of <strong>ZSSK</strong> <strong>CARGO</strong> decided to commence a reconstruction<br />

of the transhipment complex in Čierna nad Tisou in 2007.<br />

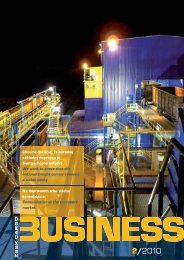

In order to equip this centre with the most modern techniques and<br />

technology, the company concluded a contract with a strategic<br />

partner. This partnership enabled the launch of pilot operation of<br />

a modern rotary tippler on high loading platform III in Čierna nad Tisou<br />

in December 2009.<br />

In addition to shorter stays of broad-gauge wagons, the modern<br />

technology enables to eliminate the risk of damage to wagons. This<br />

will bring along a reduction of financial costs to the company and<br />

will also simplify the logistics of transportations of block trains from<br />

standard gauge. We must also mention a positive environmental<br />

impact of transhipment on the environment and working conditions<br />

of employees. The rotary tippler, together with reconstructed thawing<br />

plant, enables to carry out transhipments all year long.<br />

a rekonštrukciami<br />

tippler to unload the substrate from one broad-gauge wagon within five<br />

minutes.<br />

High loading platform III – parameters<br />

Length of the complex: 445 m<br />

Length capacity of the platform - broad gauge track (BG): 27 wagons<br />

of BG<br />

Length capacity of the standard gauge track (SG): 33 wagons of SG<br />

Time of manipulation and unloading of 27 broad-gauge wagons:<br />

2.84 hours.<br />

Daily capacity of rotary tippler: 14.472 tonnes of substrate<br />

Monika SCHMIDTOVÁ<br />

Communication and International Affairs Office<br />

Rotačný výklopník v pohybe bez vozňa...<br />

Moving rotary tippler without a wagon...<br />

... a s naloženým širokorozchodným vozňom.<br />

... and with loaded broad-gauge wagon.<br />

Pracovisko velína je vybavené modernou počítačovou a audiovizuálnou technikou,<br />

ktorá umožňuje sledovať činnosť aj priamo v zariadení rotačného výklopníka.<br />

Central control room workplace is equipped with modern computer and<br />

audiovisual technology, which enables to monitor activities directly in the<br />

facility of rotary tippler.<br />

Pod násypníkom sú pristavené vozne normálneho rozchodu, ktoré sa plnia<br />

zhora. Pod násypkou je statická koľajová váha, ktorá umožňuje váženie<br />

nákladu.<br />

Below the hopper, there are standard-gauge wagons available. These are filled<br />

from above. Below the hopper, there is a static wagon weighbridge, which<br />

allows weighing of cargo.<br />

Po vyklopení sa železná ruda vysype do zásobníkov, odtiaľ sa pomocou<br />

zhrňovača dostane na kryté dopravné pásy (na fotografii vpravo), ktoré ju<br />

transportujú cez násypky do vozňa normálneho rozchodu alebo na skládku<br />

pod mostom vysokej rampy.<br />

After unloading, the iron ore is spilled into stackers. Then, by means of<br />

a diverter, it gets to covered conveyor belts (photo right), which transport it<br />

through the hopper into the standard-gauge wagon or to the stock-pile under<br />

the bridge of high loading platform.<br />

36/37