CARGO BUSINESS 1-10.indd - ZSSK Cargo

CARGO BUSINESS 1-10.indd - ZSSK Cargo

CARGO BUSINESS 1-10.indd - ZSSK Cargo

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

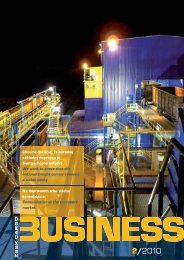

Company <strong>ZSSK</strong> <strong>CARGO</strong> launched the pilot operation of reconstructed<br />

re-pumping complex in Čierna nad Tisou on 23.October. The opening<br />

ceremony was attended by representatives of the Ministry of<br />

Transport, Posts and Telecommunications of the Slovak Republic,<br />

state administration, and local self-government and <strong>ZSSK</strong> <strong>CARGO</strong><br />

management.<br />

In order to address the environmental issues and re-pumping<br />

technology, several analyses were carried out between 2005 and<br />

2007. The findings showed that the complex (labelled 6/8) did not<br />

meet the specific requirements with regard to the environment,<br />

occupational health and safety of operating personnel.<br />

- The purpose of reconstruction was to meet severe legislative<br />

requirements for re-pumping complexes, primarily in terms of<br />

environmental legislation and capacity parameters. We have also<br />

increased the number of stations – re-pumping technologies - from<br />

six to eight, allowing 8 broad-gauge wagons to be simultaneously repumped<br />

into 8 standard-gauge wagons – emphasized the Chairman<br />

of the Board of Directors and CEO of <strong>ZSSK</strong> <strong>CARGO</strong> Mr. Matej Augustín<br />

during the complex opening.<br />

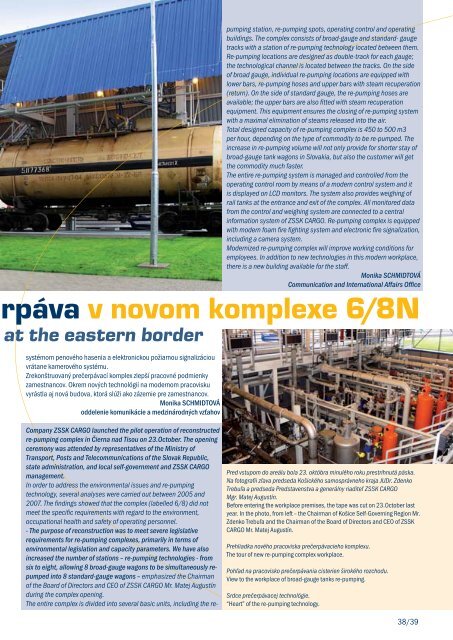

The entire complex is divided into several basic units, including the repumping<br />

station, re-pumping spots, operating control and operating<br />

buildings. The complex consists of broad-gauge and standard- gauge<br />

tracks with a station of re-pumping technology located between them.<br />

Re-pumping locations are designed as double-track for each gauge;<br />

the technological channel is located between the tracks. On the side<br />

of broad gauge, individual re-pumping locations are equipped with<br />

lower bars, re-pumping hoses and upper bars with steam recuperation<br />

(return). On the side of standard gauge, the re-pumping hoses are<br />

available; the upper bars are also fitted with steam recuperation<br />

equipment. This equipment ensures the closing of re-pumping system<br />

with a maximal elimination of steams released into the air.<br />

Total designed capacity of re-pumping complex is 450 to 500 m3<br />

per hour, depending on the type of commodity to be re-pumped. The<br />

increase in re-pumping volume will not only provide for shorter stay of<br />

broad-gauge tank wagons in Slovakia, but also the customer will get<br />

the commodity much faster.<br />

The entire re-pumping system is managed and controlled from the<br />

operating control room by means of a modern control system and it<br />

is displayed on LCD monitors. The system also provides weighing of<br />

rail tanks at the entrance and exit of the complex. All monitored data<br />

from the control and weighing system are connected to a central<br />

information system of <strong>ZSSK</strong> <strong>CARGO</strong>. Re-pumping complex is equipped<br />

with modern foam fire fighting system and electronic fire signalization,<br />

including a camera system.<br />

Modernized re-pumping complex will improve working conditions for<br />

employees. In addition to new technologies in this modern workplace,<br />

there is a new building available for the staff.<br />

Monika SCHMIDTOVÁ<br />

Communication and International Affairs Office<br />

rpáva v novom komplexe 6/8N<br />

at the eastern border<br />

systémom penového hasenia a elektronickou požiarnou signalizáciou<br />

vrátane kamerového systému.<br />

Zrekonštruovaný prečerpávací komplex zlepší pracovné podmienky<br />

zamestnancov. Okrem nových technológií na modernom pracovisku<br />

vyrástla aj nová budova, ktorá slúži ako zázemie pre zamestnancov.<br />

Monika SCHMIDTOVÁ<br />

oddelenie komunikácie a medzinárodných vzťahov<br />

Pred vstupom do areálu bola 23. októbra minulého roku prestrihnutá páska.<br />

Na fotografii zľava predseda Košického samosprávneho kraja JUDr. Zdenko<br />

Trebuľa a predseda Predstavenstva a generálny riaditeľ <strong>ZSSK</strong> <strong>CARGO</strong><br />

Mgr. Matej Augustín.<br />

Before entering the workplace premises, the tape was cut on 23.October last<br />

year. In the photo, from left – the Chairman of Košice Self-Governing Region Mr.<br />

Zdenko Trebuľa and the Chairman of the Board of Directors and CEO of <strong>ZSSK</strong><br />

<strong>CARGO</strong> Mr. Matej Augustín.<br />

Prehliadka nového pracoviska prečerpávacieho komplexu.<br />

The tour of new re-pumping complex workplace.<br />

Pohľad na pracovisko prečerpávania cisterien širokého rozchodu.<br />

View to the workplace of broad-gauge tanks re-pumping.<br />

Srdce prečerpávacej technológie.<br />

“Heart” of the re-pumping technology.<br />

38/39