You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

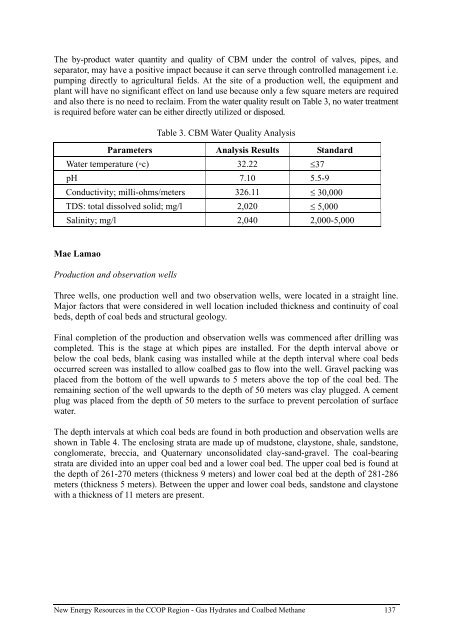

The by-product water quantity and quality of CBM under the control of valves, pipes, and<br />

separator, may have a positive impact because it can serve through controlled management i.e.<br />

pumping directly to agricultural fields. At the site of a production well, the equipment and<br />

plant will have no significant effect on land use because only a few square meters are required<br />

and also there is no need to reclaim. From the water quality result on Table 3, no water treatment<br />

is required before water can be either directly utilized or disposed.<br />

Table 3. CBM Water Quality Analysis<br />

Parameters Analysis Results Standard<br />

Water temperature (◦c) 32.22 ≤37<br />

pH 7.10 5.5-9<br />

Conductivity; milli-ohms/meters 326.11 ≤ 30,000<br />

TDS: total dissolved solid; mg/l 2,020 ≤ 5,000<br />

Salinity; mg/l 2,040 2,000-5,000<br />

Mae Lamao<br />

Production and observation wells<br />

Three wells, one production well and two observation wells, were located in a straight line.<br />

Major factors that were considered in well location included thickness and continuity of coal<br />

beds, depth of coal beds and structural geology.<br />

Final completion of the production and observation wells was commenced after drilling was<br />

completed. This is the stage at which pipes are installed. For the depth interval above or<br />

below the coal beds, blank casing was installed while at the depth interval where coal beds<br />

occurred screen was installed to allow coalbed <strong>gas</strong> to flow into the well. Gravel packing was<br />

placed from the bottom of the well upwards to 5 meters above the top of the coal bed. The<br />

remaining section of the well upwards to the depth of 50 meters was clay plugged. A cement<br />

plug was placed from the depth of 50 meters to the surface to prevent percolation of surface<br />

water.<br />

The depth intervals at which coal beds are found in both production and observation wells are<br />

shown in Table 4. The enclosing strata are made up of mudstone, claystone, shale, sandstone,<br />

conglomerate, breccia, and Quaternary unconsolidated clay-sand-gravel. The coal-bearing<br />

strata are divided into an upper coal bed and a lower coal bed. The upper coal bed is found at<br />

the depth of 261-270 meters (thickness 9 meters) and lower coal bed at the depth of 281-286<br />

meters (thickness 5 meters). Between the upper and lower coal beds, sandstone and claystone<br />

with a thickness of 11 meters are present.<br />

New Energy Resources in the <strong>CCOP</strong> Region - Gas Hydrates and Coalbed Methane 137