Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TRANSMISSION-KM SERIES 207<br />

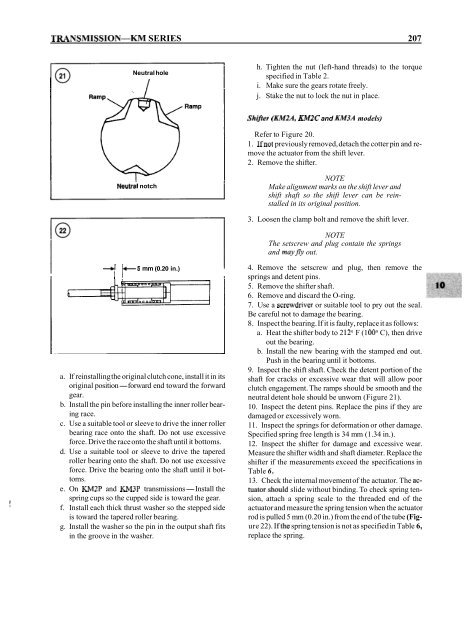

Neutral hole<br />

I<br />

h. Tighten the nut (left-hand threads) to the torque<br />

specified in Table 2.<br />

i. Make sure the gears rotate freely.<br />

j. Stake the nut to lock the nut in place.<br />

Shifter (KM2A, KM2C and KM3A models)<br />

Refer to Figure 20.<br />

1. Ifnot previously removed, detach the cotter pin and remove<br />

the actuator from the shift lever.<br />

2. Remove the shifter.<br />

~eutra'l notch<br />

NOTE<br />

Make alignment marks on the shift lever and<br />

shift shaft so the shift lever can be reinstalled<br />

in its original position.<br />

3. Loosen the clamp bolt and remove the shift lever.<br />

I t 5 mm (0.20 in.)<br />

a. If reinstalling the original clutch cone, install it in its<br />

original position-forward end toward the forward<br />

gear.<br />

b. Install the pin before installing the inner roller bearing<br />

race.<br />

c. Use a suitable tool or sleeve to drive the inner roller<br />

bearing race onto the shaft. Do not use excessive<br />

force. Drive the race onto the shaft until it bottoms.<br />

d. Use a suitable tool or sleeve to drive the tapered<br />

roller bearing onto the shaft. Do not use excessive<br />

force. Drive the bearing onto the shaft until it bottoms.<br />

e. On KM2P and KM3P transmissions-Install the<br />

spring cups so the cupped side is toward the gear.<br />

f. Install each thick thrust washer so the stepped side<br />

is toward the tapered roller bearing.<br />

g. Install the washer so the pin in the output shaft fits<br />

in the groove in the washer.<br />

NOTE<br />

The setscrew and plug contain the springs<br />

and mayfly out.<br />

4. Remove the setscrew and plug, then remove the<br />

springs and detent pins.<br />

5. Remove the shifter shaft.<br />

6. Remove and discard the O-ring.<br />

7. Use a screwdriver or suitable tool to pry out the seal.<br />

Be careful not to damage the bearing.<br />

8. Inspect the bearing. If it is faulty, replace it as follows:<br />

a. Heat the shifter body to 2 12O F (1 00° C), then drive<br />

out the bearing.<br />

b. Install the new bearing with the stamped end out.<br />

Push in the bearing until it bottoms.<br />

9. Inspect the shift shaft. Check the detent portion of the<br />

shaft for cracks or excessive wear that will allow poor<br />

clutch engagement. The ramps should be smooth and the<br />

neutral detent hole should be unworn (Figure 21).<br />

10. Inspect the detent pins. Replace the pins if they are<br />

damaged or excessively worn.<br />

11. Inspect the springs for deformation or other damage.<br />

Specified spring free length is 34 mm (1.34 in.).<br />

12. Inspect the shifter for damage and excessive wear.<br />

Measure the shifter width and shaft diameter. Replace the<br />

shifter if the measurements exceed the specifications in<br />

Table 6.<br />

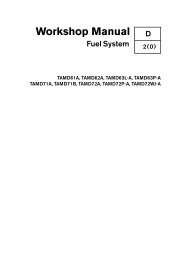

13. Check the internal movement of the actuator. The actuator.should<br />

slide without binding. To check spring tension,<br />

attach a spring scale to the threaded end of the<br />

actuator and measure the spring tension when the actuator<br />

rod is pulled 5 mm (0.20 in.) from the end of the tube (Figure<br />

22). Ifthe spring tension is not as specified in Table 6,<br />

replace the spring.