Literature Review on Building Envelope, Heating and ... - Beeshive.org

Literature Review on Building Envelope, Heating and ... - Beeshive.org

Literature Review on Building Envelope, Heating and ... - Beeshive.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

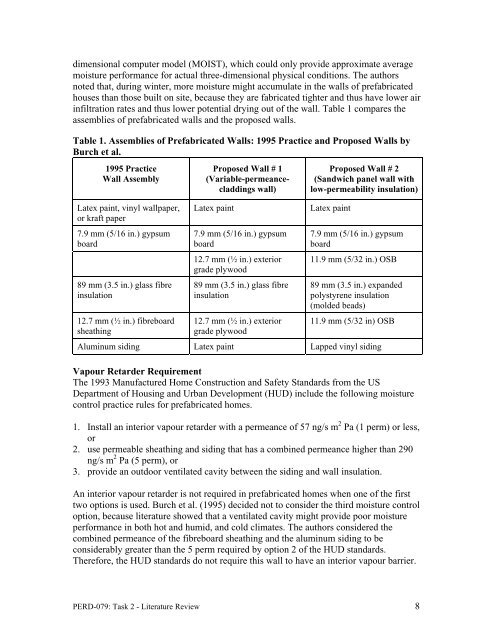

dimensi<strong>on</strong>al computer model (MOIST), which could <strong>on</strong>ly provide approximate average<br />

moisture performance for actual three-dimensi<strong>on</strong>al physical c<strong>on</strong>diti<strong>on</strong>s. The authors<br />

noted that, during winter, more moisture might accumulate in the walls of prefabricated<br />

houses than those built <strong>on</strong> site, because they are fabricated tighter <strong>and</strong> thus have lower air<br />

infiltrati<strong>on</strong> rates <strong>and</strong> thus lower potential drying out of the wall. Table 1 compares the<br />

assemblies of prefabricated walls <strong>and</strong> the proposed walls.<br />

Table 1. Assemblies of Prefabricated Walls: 1995 Practice <strong>and</strong> Proposed Walls by<br />

Burch et al.<br />

1995 Practice<br />

Wall Assembly<br />

Proposed Wall # 1<br />

(Variable-permeancecladdings<br />

wall)<br />

Proposed Wall # 2<br />

(S<strong>and</strong>wich panel wall with<br />

low-permeability insulati<strong>on</strong>)<br />

Latex paint, vinyl wallpaper,<br />

or kraft paper<br />

7.9 mm (5/16 in.) gypsum<br />

board<br />

89 mm (3.5 in.) glass fibre<br />

insulati<strong>on</strong><br />

12.7 mm (½ in.) fibreboard<br />

sheathing<br />

Latex paint<br />

7.9 mm (5/16 in.) gypsum<br />

board<br />

12.7 mm (½ in.) exterior<br />

grade plywood<br />

89 mm (3.5 in.) glass fibre<br />

insulati<strong>on</strong><br />

12.7 mm (½ in.) exterior<br />

grade plywood<br />

Latex paint<br />

7.9 mm (5/16 in.) gypsum<br />

board<br />

11.9 mm (5/32 in.) OSB<br />

89 mm (3.5 in.) exp<strong>and</strong>ed<br />

polystyrene insulati<strong>on</strong><br />

(molded beads)<br />

11.9 mm (5/32 in) OSB<br />

Aluminum siding Latex paint Lapped vinyl siding<br />

Vapour Retarder Requirement<br />

The 1993 Manufactured Home C<strong>on</strong>structi<strong>on</strong> <strong>and</strong> Safety St<strong>and</strong>ards from the US<br />

Department of Housing <strong>and</strong> Urban Development (HUD) include the following moisture<br />

c<strong>on</strong>trol practice rules for prefabricated homes.<br />

1. Install an interior vapour retarder with a permeance of 57 ng/s m 2 Pa (1 perm) or less,<br />

or<br />

2. use permeable sheathing <strong>and</strong> siding that has a combined permeance higher than 290<br />

ng/s m 2 Pa (5 perm), or<br />

3. provide an outdoor ventilated cavity between the siding <strong>and</strong> wall insulati<strong>on</strong>.<br />

An interior vapour retarder is not required in prefabricated homes when <strong>on</strong>e of the first<br />

two opti<strong>on</strong>s is used. Burch et al. (1995) decided not to c<strong>on</strong>sider the third moisture c<strong>on</strong>trol<br />

opti<strong>on</strong>, because literature showed that a ventilated cavity might provide poor moisture<br />

performance in both hot <strong>and</strong> humid, <strong>and</strong> cold climates. The authors c<strong>on</strong>sidered the<br />

combined permeance of the fibreboard sheathing <strong>and</strong> the aluminum siding to be<br />

c<strong>on</strong>siderably greater than the 5 perm required by opti<strong>on</strong> 2 of the HUD st<strong>and</strong>ards.<br />

Therefore, the HUD st<strong>and</strong>ards do not require this wall to have an interior vapour barrier.<br />

PERD-079: Task 2 - <str<strong>on</strong>g>Literature</str<strong>on</strong>g> <str<strong>on</strong>g>Review</str<strong>on</strong>g> 8