Lightweight Concrete for High Strength - Expanded Shale & Clay

Lightweight Concrete for High Strength - Expanded Shale & Clay

Lightweight Concrete for High Strength - Expanded Shale & Clay

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C.2 Girder Construction<br />

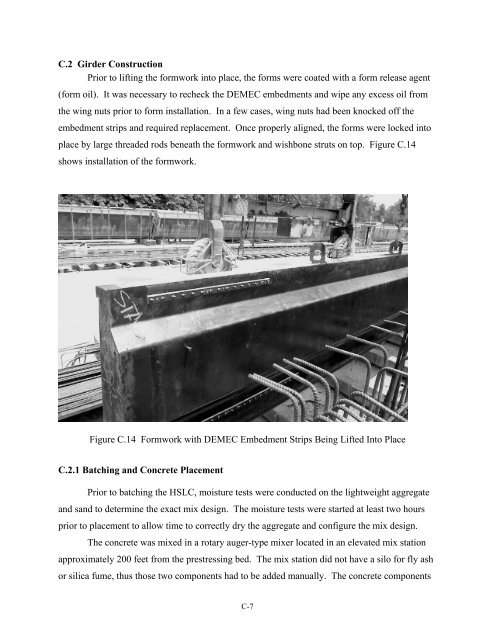

Prior to lifting the <strong>for</strong>mwork into place, the <strong>for</strong>ms were coated with a <strong>for</strong>m release agent<br />

(<strong>for</strong>m oil). It was necessary to recheck the DEMEC embedments and wipe any excess oil from<br />

the wing nuts prior to <strong>for</strong>m installation. In a few cases, wing nuts had been knocked off the<br />

embedment strips and required replacement. Once properly aligned, the <strong>for</strong>ms were locked into<br />

place by large threaded rods beneath the <strong>for</strong>mwork and wishbone struts on top. Figure C.14<br />

shows installation of the <strong>for</strong>mwork.<br />

Figure C.14 Formwork with DEMEC Embedment Strips Being Lifted Into Place<br />

C.2.1 Batching and <strong>Concrete</strong> Placement<br />

Prior to batching the HSLC, moisture tests were conducted on the lightweight aggregate<br />

and sand to determine the exact mix design. The moisture tests were started at least two hours<br />

prior to placement to allow time to correctly dry the aggregate and configure the mix design.<br />

The concrete was mixed in a rotary auger-type mixer located in an elevated mix station<br />

approximately 200 feet from the prestressing bed. The mix station did not have a silo <strong>for</strong> fly ash<br />

or silica fume, thus those two components had to be added manually. The concrete components<br />

C-7