Lightweight Concrete for High Strength - Expanded Shale & Clay

Lightweight Concrete for High Strength - Expanded Shale & Clay

Lightweight Concrete for High Strength - Expanded Shale & Clay

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

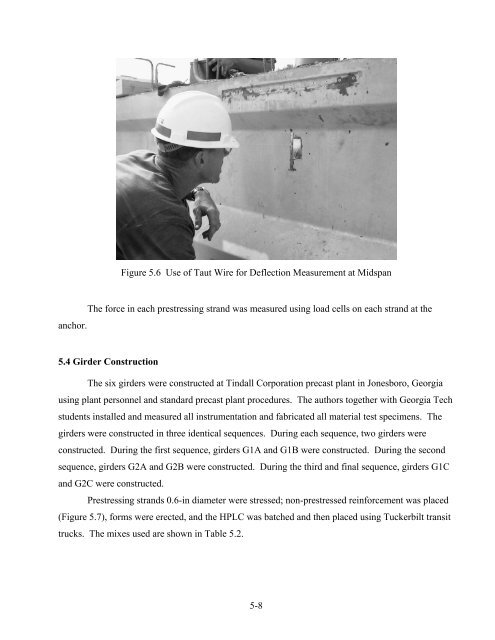

Figure 5.6 Use of Taut Wire <strong>for</strong> Deflection Measurement at Midspan<br />

The <strong>for</strong>ce in each prestressing strand was measured using load cells on each strand at the<br />

anchor.<br />

5.4 Girder Construction<br />

The six girders were constructed at Tindall Corporation precast plant in Jonesboro, Georgia<br />

using plant personnel and standard precast plant procedures. The authors together with Georgia Tech<br />

students installed and measured all instrumentation and fabricated all material test specimens. The<br />

girders were constructed in three identical sequences. During each sequence, two girders were<br />

constructed. During the first sequence, girders G1A and G1B were constructed. During the second<br />

sequence, girders G2A and G2B were constructed. During the third and final sequence, girders G1C<br />

and G2C were constructed.<br />

Prestressing strands 0.6-in diameter were stressed; non-prestressed rein<strong>for</strong>cement was placed<br />

(Figure 5.7), <strong>for</strong>ms were erected, and the HPLC was batched and then placed using Tuckerbilt transit<br />

trucks. The mixes used are shown in Table 5.2.<br />

5-8