Lightweight Concrete for High Strength - Expanded Shale & Clay

Lightweight Concrete for High Strength - Expanded Shale & Clay

Lightweight Concrete for High Strength - Expanded Shale & Clay

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

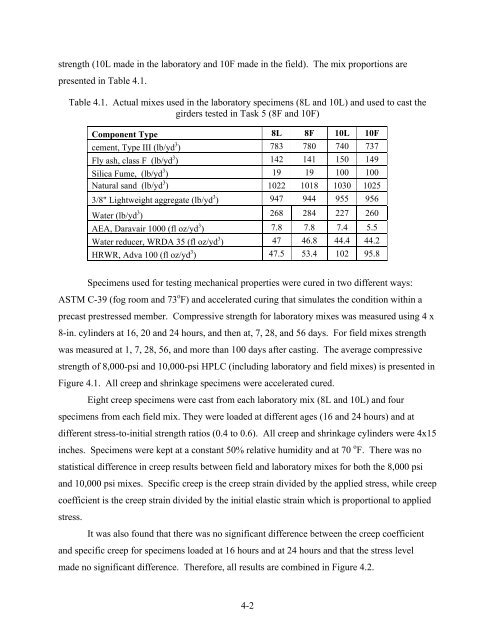

strength (10L made in the laboratory and 10F made in the field). The mix proportions are<br />

presented in Table 4.1.<br />

Table 4.1. Actual mixes used in the laboratory specimens (8L and 10L) and used to cast the<br />

girders tested in Task 5 (8F and 10F)<br />

Component Type 8L 8F 10L 10F<br />

cement, Type III (lb/yd 3 ) 783 780 740 737<br />

Fly ash, class F (lb/yd 3 ) 142 141 150 149<br />

Silica Fume, (lb/yd 3 ) 19 19 100 100<br />

Natural sand (lb/yd 3 ) 1022 1018 1030 1025<br />

3/8" <strong>Lightweight</strong> aggregate (lb/yd 3 ) 947 944 955 956<br />

Water (lb/yd 3 ) 268 284 227 260<br />

AEA, Daravair 1000 (fl oz/yd 3 ) 7.8 7.8 7.4 5.5<br />

Water reducer, WRDA 35 (fl oz/yd 3 ) 47 46.8 44.4 44.2<br />

HRWR, Adva 100 (fl oz/yd 3 ) 47.5 53.4 102 95.8<br />

Specimens used <strong>for</strong> testing mechanical properties were cured in two different ways:<br />

ASTM C-39 (fog room and 73 o F) and accelerated curing that simulates the condition within a<br />

precast prestressed member. Compressive strength <strong>for</strong> laboratory mixes was measured using 4 x<br />

8-in. cylinders at 16, 20 and 24 hours, and then at, 7, 28, and 56 days. For field mixes strength<br />

was measured at 1, 7, 28, 56, and more than 100 days after casting. The average compressive<br />

strength of 8,000-psi and 10,000-psi HPLC (including laboratory and field mixes) is presented in<br />

Figure 4.1. All creep and shrinkage specimens were accelerated cured.<br />

Eight creep specimens were cast from each laboratory mix (8L and 10L) and four<br />

specimens from each field mix. They were loaded at different ages (16 and 24 hours) and at<br />

different stress-to-initial strength ratios (0.4 to 0.6). All creep and shrinkage cylinders were 4x15<br />

inches. Specimens were kept at a constant 50% relative humidity and at 70 o F. There was no<br />

statistical difference in creep results between field and laboratory mixes <strong>for</strong> both the 8,000 psi<br />

and 10,000 psi mixes. Specific creep is the creep strain divided by the applied stress, while creep<br />

coefficient is the creep strain divided by the initial elastic strain which is proportional to applied<br />

stress.<br />

It was also found that there was no significant difference between the creep coefficient<br />

and specific creep <strong>for</strong> specimens loaded at 16 hours and at 24 hours and that the stress level<br />

made no significant difference. There<strong>for</strong>e, all results are combined in Figure 4.2.<br />

4-2