- Page 1: Wambo Coal Pty LimitedAnnual Enviro

- Page 4 and 5: 2010-2011 AEMR2.8 Water Management.

- Page 6 and 7: 2010-2011 AEMR3.13.1.3 Aboriginal C

- Page 8 and 9: 2010-2011 AEMRList of FiguresFigure

- Page 10 and 11: List of Appendices2010-2011 AEMRApp

- Page 12 and 13: 2010-2011 AEMR1.0 Introduction1.1 S

- Page 14 and 15: 2010-2011 AEMRTable 1.0 - Annual Re

- Page 16 and 17: JERRYS PLAINS 15kmCOAL & ALLIEDRIVE

- Page 18 and 19: 2010-2011 AEMRTable 1.2 - WCPL Mini

- Page 20 and 21: 2010-2011 AEMR1.3.3 Environmental P

- Page 22 and 23: 5UNITED COLLIERYGOLDENGW16GW17WOMBA

- Page 24 and 25: 2010-2011 AEMR1.3.7 Subsidence Mana

- Page 26 and 27: 2010-2011 AEMR1.5 Review of 2009-20

- Page 28 and 29: 2010-2011 AEMRNo DoPI Issue DoPI Ac

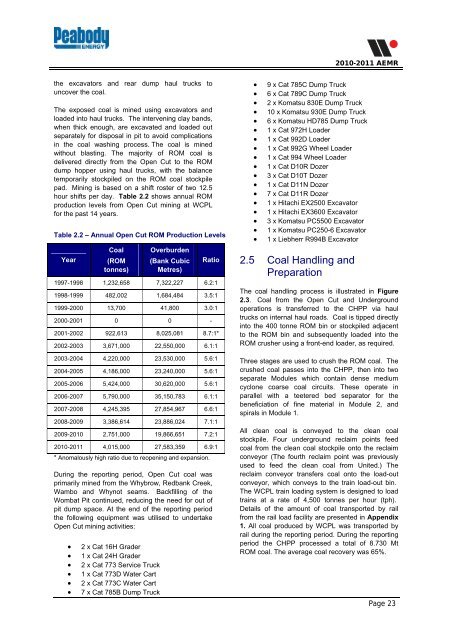

- Page 30 and 31: 2010-2011 AEMROpen CutDuring the re

- Page 32 and 33: 2010-2011 AEMRTable 2.1 - Productio

- Page 36 and 37: 2010-2011 AEMRFigure 2.3 - Coal Han

- Page 38 and 39: 2010-2011 AEMRhydrocarbon spill res

- Page 40 and 41: 2010-2011 AEMRTable 2.3 - Stored Wa

- Page 42 and 43: 2010-2011 AEMRTable 2.4 - WCPL Wast

- Page 44 and 45: 2010-2011 AEMRAs discussed in the l

- Page 46 and 47: 2010-2011 AEMR3.0 EnvironmentalMana

- Page 48 and 49: 2010-2011 AEMRWambo Coal Weather St

- Page 50 and 51: 2010-2011 AEMRFigure 3.5 - 2010-201

- Page 52 and 53: 2010-2011 AEMRIn accordance with Co

- Page 54 and 55: 2010-2011 AEMRTotal Suspended Parti

- Page 56 and 57: 2010-2011 AEMR3.2.2.3 Dust Depositi

- Page 58 and 59: 2010-2011 AEMR3.3 Erosion & Sedimen

- Page 60 and 61: 2010-2011 AEMRTrigger levels for EC

- Page 62 and 63: 2010-2011 AEMRWollombi Brook record

- Page 64 and 65: 2010-2011 AEMRNovember and December

- Page 66 and 67: GW20GW16 GW17 GW19P1P11P3NORTH WAMB

- Page 68 and 69: 2010-2011 AEMRUnited Collieries Pie

- Page 70 and 71: 2010-2011 AEMR3.7.2.2 Acacia Specie

- Page 72 and 73: V10-A2NORTH WAMBOCREEK DIVERSIONV10

- Page 74 and 75: 2010-2011 AEMR3.8 Weeds3.8.1 Enviro

- Page 76 and 77: 2010-2011 AEMR1252010 - 2011 AEMR B

- Page 78 and 79: 2010-2011 AEMRDayL Aeq(15 minute)Ta

- Page 80 and 81: 2010-2011 AEMRAttended Noise Monito

- Page 82 and 83: WARNINGNo part of this plan should

- Page 84 and 85:

2010-2011 AEMRGain advice on most s

- Page 86 and 87:

2010-2011 AEMRWith the commencement

- Page 88 and 89:

2010-2011 AEMRfive complaints recor

- Page 90 and 91:

2010-2011 AEMRNo. of complaints1098

- Page 92 and 93:

2010-2011 AEMRSingleton Public Scho

- Page 94 and 95:

2010-2011 AEMRTable 5.2 - Maintenan

- Page 96 and 97:

2010-2011 AEMRNETD Rehabilitation w

- Page 98 and 99:

2010-2011 AEMRtransects had a simil

- Page 100 and 101:

Appendix 1Rail Haulage Records

- Page 102 and 103:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 104 and 105:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 106 and 107:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 108 and 109:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 110 and 111:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 112 and 113:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 114 and 115:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 116 and 117:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 118 and 119:

Wambo Coal Pty Ltd2010-2011 AEMRTon

- Page 120 and 121:

Appendix 2Environmental MonitoringP

- Page 122 and 123:

Annual Environmental Management Rep

- Page 124 and 125:

Wambo Coal Pty Ltd2010 - 2011 AEMRL

- Page 126 and 127:

Annual Environmental Management Rep

- Page 128 and 129:

Annual Environmental Management Rep

- Page 130 and 131:

876543210Annual Environmental Manag

- Page 132 and 133:

Annual Environmental Management Rep

- Page 134 and 135:

Wambo Coal Pty Ltd2010-2011 AEMRDat

- Page 136 and 137:

Wambo Coal Pty Limited2010-2011 AEM

- Page 138 and 139:

Wambo Coal Pty Limited2010-2011 AEM

- Page 140 and 141:

Wambo Coal Pty Limited2010-2011 AEM

- Page 142 and 143:

Wambo Coal Pty Limited2010-2011 AEM

- Page 144 and 145:

Annual Environmental Management Rep

- Page 146 and 147:

Annual Environmental Management Rep

- Page 148 and 149:

Annual Environmental Management Rep

- Page 150 and 151:

Annual Environmental Management Rep

- Page 152 and 153:

Wambo Coal Pty Limited2010-2011 AEM

- Page 154 and 155:

FM8 - Cross Section - 21 June 20113

- Page 156 and 157:

FM6 - Cross Section 21 June 201143.

- Page 158 and 159:

FM4 - Cross Section 21 June 201110.

- Page 160 and 161:

FM2 - Cross Section 21 July 201143.

- Page 162 and 163:

HYDROGRAPHIC STATIONFM9 - SOUTH WAM

- Page 164 and 165:

HYDROGRAPHIC STATIONFM7 - Stony Cre

- Page 166 and 167:

HYDROGRAPHIC STATIONFM5 - South Wam

- Page 168 and 169:

HYDROGRAPHIC STATIONFM3 - Lower Wam

- Page 170 and 171:

HYDROGRAPHIC STATIONFM1 - Upper Wam

- Page 172 and 173:

Annual Environmental Management Rep

- Page 174 and 175:

Annual Environmental Management Rep

- Page 176 and 177:

Annual Environmental Management Rep

- Page 178 and 179:

Annual Environmental Management Rep

- Page 180 and 181:

Annual Environmental Management Rep

- Page 182 and 183:

Annual Environmental Management Rep

- Page 184 and 185:

Annual Environmental Management Rep

- Page 186 and 187:

10.09.08.07.06.05.0Annual Environme

- Page 188 and 189:

Annual Environmental Management Rep

- Page 190 and 191:

Wambo Coal MineAnnual Report_______

- Page 192 and 193:

EXECUTIVE SUMMARYGlobal Acoustics w

- Page 194 and 195:

Table of Contents1 INTRODUCTION....

- Page 196 and 197:

The survey purpose is to quantify a

- Page 198 and 199:

1.3 TerminologySome definitions of

- Page 200 and 201:

1.5 Wambo Coal Rail Spur Developmen

- Page 202 and 203:

2 METHODOLOGY2.1 Assessment Method2

- Page 204 and 205:

Table 3.2 L A1(1 minute) dB GENERAT

- Page 206 and 207:

Table 3.4 L A1(1 minute) dB GENERAT

- Page 208 and 209:

Table 3.6 L A1(1 minute) dB GENERAT

- Page 210 and 211:

Table 3.8 L A1(1 minute) dB GENERAT

- Page 212 and 213:

Table 3.10L A1(1 minute) dB GENERAT

- Page 214 and 215:

Table 3.12 L A1(1 minute) dB GENERA

- Page 216 and 217:

Table 3.14 L A1(1 minute) dB GENERA

- Page 218 and 219:

Table 3.16 L A1(1 minute) dB GENERA

- Page 220 and 221:

4 SUMMARY OF COMPLIANCE4.1 SummaryN

- Page 222 and 223:

DayEvening/NightNightLand NumberL A

- Page 224 and 225:

A.2 Wambo Rail Spur Development Con

- Page 226 and 227:

compliance with the LAeq(15 minute)

- Page 228 and 229:

2010 Annual EcologicalMonitoring Re

- Page 230 and 231:

Executive SummaryRPS Australia East

- Page 232 and 233:

ContentsEXECUTIVE SUMMARYI1 INTRODU

- Page 234 and 235:

1 IntroductionRPS Australia East (R

- Page 236 and 237:

1.2 Qualifications and Licensing1.2

- Page 238 and 239:

Figure 2-1: Locations of Flora Moni

- Page 240 and 241:

• In 2007 all quadrats recorded i

- Page 242 and 243:

2.3 Discussion2.3.1 Species Diversi

- Page 244 and 245:

species specific herbicide), no con

- Page 246 and 247:

3 FaunaFive types of targeted surve

- Page 248 and 249:

Bird survey locations are not marke

- Page 250 and 251:

Figure 3-2: Threatened Species Loca

- Page 252 and 253:

Species Abundance in 2010The number

- Page 254 and 255:

• Observer bias. Likely variation

- Page 256 and 257:

Common Brushtail Possum was identif

- Page 258 and 259:

• Understorey characteristics;•

- Page 260 and 261:

Figure 4-2: Riparian Section Condit

- Page 262 and 263:

Sections• A relatively high numbe

- Page 264 and 265:

4.4 RecommendationsImplementation o

- Page 266 and 267:

Appendix 3Summary ofEnvironmental I

- Page 268 and 269:

Wambo Coal Pty Limited2010-2011 AEM

- Page 270 and 271:

Wambo Coal Pty Limited2010-2011 AEM

- Page 272 and 273:

Appendix 4Register of CommunityComp

- Page 274 and 275:

Wambo Coal Pty Limited2010-2011 AEM

- Page 276 and 277:

NoDate & TimeReceivedNature of Comp

- Page 278 and 279:

Appendix 5Rehabilitation Plan

- Page 280 and 281:

aemcWambo Coal Mine, Rail Loop and

- Page 282 and 283:

aemcWambo Coal Mine, Rail Loop and

- Page 284 and 285:

aemcWambo Coal Mine, Rail Loop and

- Page 286 and 287:

aemcWambo Coal Mine, Rail Loop and

- Page 288 and 289:

aemcWambo Coal Mine, Rail Loop and

- Page 290 and 291:

aemcWambo Coal Mine, Rail Loop and

- Page 292 and 293:

aemcWambo Coal Mine, Rail Loop and

- Page 294 and 295:

aemcWambo Coal Mine, Rail Loop and

- Page 296 and 297:

aemcWambo Coal Mine, Rail Loop and

- Page 298 and 299:

aemcWambo Coal Mine, Rail Loop and

- Page 300 and 301:

aemcWambo Coal Mine, Rail Loop and

- Page 302 and 303:

aemcWambo Coal Mine, Rail Loop and

- Page 304 and 305:

aemcWambo Coal Mine, Rail Loop and

- Page 306 and 307:

aemcWambo Coal Mine, Rail Loop and

- Page 308 and 309:

aemcWambo Coal Mine, Rail Loop and

- Page 310 and 311:

aemcWambo Coal Mine, Rail Loop and

- Page 312 and 313:

aemcWambo Coal Mine, Rail Loop and

- Page 314 and 315:

aemcWambo Coal Mine, Rail Loop and

- Page 316 and 317:

aemcWambo Coal Mine, Rail Loop and

- Page 318 and 319:

aemcWambo Coal Mine, Rail Loop and

- Page 320 and 321:

aemcWambo Coal Mine, Rail Loop and

- Page 322 and 323:

aemcWambo Coal Mine, Rail Loop and

- Page 324 and 325:

aemcWambo Coal Mine, Rail Loop and

- Page 326 and 327:

aemcWambo Coal Mine, Rail Loop and

- Page 328 and 329:

aemcWambo Coal Mine, Rail Loop and

- Page 330 and 331:

aemcWambo Coal Mine, Rail Loop and

- Page 332 and 333:

aemcWambo Coal Mine, Rail Loop and

- Page 334 and 335:

aemcWambo Coal Mine, Rail Loop and

- Page 336 and 337:

aemcWambo Coal Mine, Rail Loop and

- Page 338 and 339:

aemcWambo Coal Mine, Rail Loop and

- Page 340 and 341:

aemcWambo Coal Mine, Rail Loop and

- Page 342 and 343:

aemcWambo Coal Mine, Rail Loop and

- Page 344 and 345:

aemcWambo Coal Mine, Rail Loop and

- Page 346 and 347:

aemcWambo Coal Mine, Rail Loop and

- Page 348 and 349:

aemcWambo Coal Mine, Rail Loop and

- Page 350 and 351:

aemcWambo Coal Mine, Rail Loop and

- Page 352 and 353:

aemcWambo Coal Mine, Rail Loop and

- Page 354 and 355:

aemcWambo Coal Mine, Rail Loop and

- Page 356 and 357:

aemcWambo Coal Mine, Rail Loop and

- Page 358 and 359:

aemcWambo Coal Mine, Rail Loop and

- Page 360 and 361:

aemcWambo Coal Mine, Rail Loop and

- Page 362 and 363:

aemcWambo Coal Mine, Rail Loop and

- Page 364 and 365:

aemcWambo Coal Mine, Rail Loop and

- Page 366 and 367:

aemcWambo Coal Mine, Rail Loop and

- Page 368 and 369:

aemcWambo Coal Mine, Rail Loop and

- Page 370 and 371:

aemcWambo Coal Mine, Rail Loop and

- Page 372 and 373:

aemcWambo Coal Mine, Rail Loop and

- Page 374 and 375:

aemcWambo Coal Mine, Rail Loop and

- Page 376:

aemcWambo Coal Mine, Rail Loop and