twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

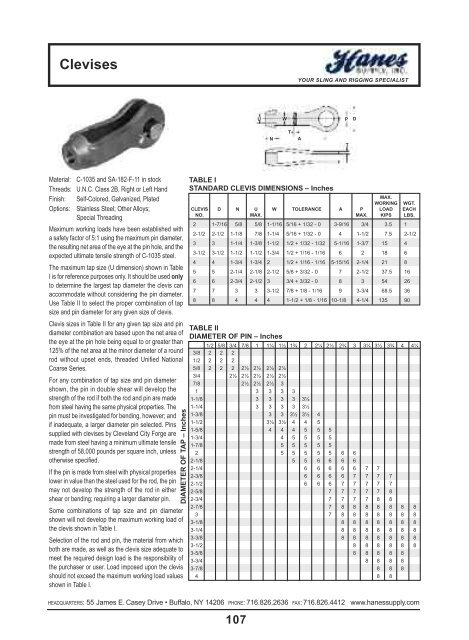

clevisesYOUR SLING AND RIGGING SPECIALISTUWPDtnatMaterial: C-1035 and SA-182-F-11 <strong>in</strong> stockThreads: U.N.C. Class 2B, Right or Left HandF<strong>in</strong>ish: Self-Colored, Galvanized, PlatedOptions: Sta<strong>in</strong>less Steel; Other Alloys;Special Thread<strong>in</strong>gMaximum work<strong>in</strong>g loads have been established witha safety factor of 5:1 us<strong>in</strong>g the maximum p<strong>in</strong> diameter,the result<strong>in</strong>g net area of the eye at the p<strong>in</strong> hole, and theexpected ultimate tensile strength of C-1035 steel.The maximum tap size (U dimension) shown <strong>in</strong> TableI is for reference purposes only. It should be used onlyto determ<strong>in</strong>e the largest tap diameter the clevis canaccommodate without consider<strong>in</strong>g the p<strong>in</strong> diameter.Use Table II to select the proper comb<strong>in</strong>ation of tapsize and p<strong>in</strong> diameter for any given size of clevis.Clevis sizes <strong>in</strong> Table II for any given tap size and p<strong>in</strong>diameter comb<strong>in</strong>ation are based upon the net area ofthe eye at the p<strong>in</strong> hole be<strong>in</strong>g equal to or greater than125% of the net area at the m<strong>in</strong>or diameter of a roundrod without upset ends, threaded Unified NationalCoarse Series.For any comb<strong>in</strong>ation of tap size and p<strong>in</strong> diametershown, the p<strong>in</strong> <strong>in</strong> double shear will develop thestrength of the rod if both the rod and p<strong>in</strong> are madefrom steel hav<strong>in</strong>g the same physical properties. Thep<strong>in</strong> must be <strong>in</strong>vestigated for bend<strong>in</strong>g, however; andif <strong>in</strong>adequate, a larger diameter p<strong>in</strong> selected. P<strong>in</strong>ssupplied with clevises by Cleveland City Forge aremade from steel hav<strong>in</strong>g a m<strong>in</strong>imum ultimate tensilestrength of 58,000 pounds per square <strong>in</strong>ch, unlessotherwise specified.If the p<strong>in</strong> is made from steel with physical propertieslower <strong>in</strong> value than the steel used for the rod, the p<strong>in</strong>may not develop the strength of the rod <strong>in</strong> eithershear or bend<strong>in</strong>g; requir<strong>in</strong>g a larger diameter p<strong>in</strong>.DIaMeteR of taP – <strong>Inc</strong>hesSome comb<strong>in</strong>ations of tap size and p<strong>in</strong> diametershown will not develop the maximum work<strong>in</strong>g load ofthe clevis shown <strong>in</strong> Table I.Selection of the rod and p<strong>in</strong>, the material from whichboth are made, as well as the clevis size adequate tomeet the required design load is the responsibility ofthe purchaser or user. Load imposed upon the clevisshould not exceed the maximum work<strong>in</strong>g load valuesshown <strong>in</strong> Table I.table IstanDaRD cleVIs DIMensIons – <strong>Inc</strong>hesMaX.WoRkInG WGt.cleVIs D n U W toleRance a P loaD eacHno. MaX. MaX. kIPs lbs.2 1-7/16 5/8 5/8 1-1/16 5/16 + 1/32 - 0 3-9/16 3/4 3.5 12-1/2 2-1/2 1-1/8 7/8 1-1/4 5/16 + 1/32 - 0 4 1-1/2 7.5 2-1/23 3 1-1/4 1-3/8 1-1/2 1/2 + 1/32 - 1/32 5-1/16 1-3/7 15 43-1/2 3-1/2 1-1/2 1-1/2 1-3/4 1/2 + 1/16 - 1/16 6 2 18 64 4 1-3/4 1-3/4 2 1/2 + 1/16 - 1/16 5-15/16 2-1/4 21 85 5 2-1/4 2-1/8 2-1/2 5/8 + 3/32 - 0 7 2-1/2 37.5 166 6 2-3/4 2-1/2 3 3/4 + 3/32 - 0 8 3 54 267 7 3 3 3-1/2 7/8 + 1/8 - 1/16 9 3-3/4 68.5 368 8 4 4 4 1-1/2 + 1/8 - 1/16 10-1/8 4-1/4 135 90table IIDIaMeteR of PIn – <strong>Inc</strong>hes1/2 5/8 3/4 7/8 1 1¼ 1½ 1¾ 2 2¼ 2½ 2¾ 3 3¼ 3½ 3¾ 4 4¼3/8 2 2 21/2 2 2 25/8 2 2 2 2½ 2½ 2½ 2½3/4 2½ 2½ 2½ 2½ 2½7/8 2½ 2½ 2½ 31 3 3 3 31-1/8 3 3 3 3 3½1-1/4 3 3 3 3 3½1-3/8 3 3 3½ 3½ 41-1/2 3½ 3½ 4 4 51-5/8 4 4 4 5 5 51-3/4 4 5 5 5 51-7/8 5 5 5 5 52 5 5 5 5 5 6 62-1/8 5 5 6 6 6 62-1/4 6 6 6 6 6 7 72-3/8 6 6 6 6 7 7 7 72-1/2 6 6 6 7 7 7 7 72-5/8 7 7 7 7 7 82-3/4 7 7 7 7 8 82-7/8 7 8 8 8 8 8 8 83 7 8 8 8 8 8 8 83-1/8 8 8 8 8 8 8 83-1/4 8 8 8 8 8 8 83-3/8 8 8 8 8 8 8 83-1/2 8 8 8 8 8 83-5/8 8 8 8 8 83-3/4 8 8 8 83-7/8 8 8 84 8 8HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com107