twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

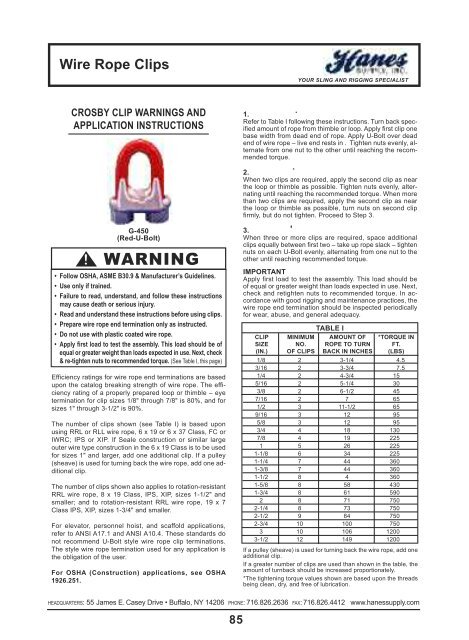

Wire Rope clipsYOUR SLING AND RIGGING SPECIALISTCROSBY CLIP WARNINGS ANDAPPLICATION INSTRUCTIONS1.Refer to Table I follow<strong>in</strong>g these <strong>in</strong>structions. Turn back specifiedamount of rope from thimble or loop. Apply first clip onebase width from dead end of rope. Apply U-Bolt over deadend of wire rope – live end rests <strong>in</strong> . Tighten nuts evenly, alternatefrom one nut to the other until reach<strong>in</strong>g the recommendedtorque.2.When two clips are required, apply the second clip as nearthe loop or thimble as possible. Tighten nuts evenly, alternat<strong>in</strong>guntil reach<strong>in</strong>g the recommended torque. When morethan two clips are required, apply the second clip as nearthe loop or thimble as possible, turn nuts on second clipfirmly, but do not tighten. Proceed to Step 3.!G-450(Red-U-bolt)WARNING• Follow OSHA, ASME B30.9 & Manufacturer’s Guidel<strong>in</strong>es.• Use only if tra<strong>in</strong>ed.• Failure to read, understand, and follow these <strong>in</strong>structionsmay cause death or serious <strong>in</strong>jury.• Read and understand these <strong>in</strong>structions before us<strong>in</strong>g clips.• Prepare wire rope end term<strong>in</strong>ation only as <strong>in</strong>structed.• Do not use with plastic coated wire rope.• Apply first load to test the assembly. This load should be ofequal or greater weight than loads expected <strong>in</strong> use. Next, check& re-tighten nuts to recommended torque. (See Table I, this page)Efficiency rat<strong>in</strong>gs for wire rope end term<strong>in</strong>ations are basedupon the catalog break<strong>in</strong>g strength of wire rope. The efficiencyrat<strong>in</strong>g of a properly prepared loop or thimble – eyeterm<strong>in</strong>ation for clip sizes 1/8" through 7/8" is 80%, and forsizes 1" through 3-1/2" is 90%.The number of clips shown (see Table I) is based uponus<strong>in</strong>g RRL or RLL wire rope, 6 x 19 or 6 x 37 Class, FC orIWRC; IPS or XIP. If Seale construction or similar largeouter wire type construction <strong>in</strong> the 6 x 19 Class is to be usedfor sizes 1" and larger, add one additional clip. If a pulley(sheave) is used for turn<strong>in</strong>g back the wire rope, add one additionalclip.The number of clips shown also applies to rotation-resistantRRL wire rope, 8 x 19 Class, IPS, XIP, sizes 1-1/2" andsmaller; and to rotation-resistant RRL wire rope, 19 x 7Class IPS, XIP, sizes 1-3/4" and smaller.For elevator, personnel hoist, and scaffold applications,refer to ANSI A17.1 and ANSI A10.4. These standards donot recommend U-Bolt style wire rope clip term<strong>in</strong>ations.The style wire rope term<strong>in</strong>ation used for any application isthe obligation of the user.for osHa (construction) applications, see osHa1926.251.3.When three or more clips are required, space additionalclips equally between first two – take up rope slack – tightennuts on each U-Bolt evenly, alternat<strong>in</strong>g from one nut to theother until reach<strong>in</strong>g recommended torque.IMPoRtantApply first load to test the assembly. This load should beof equal or greater weight than loads expected <strong>in</strong> use. Next,check and retighten nuts to recommended torque. In accordancewith good rigg<strong>in</strong>g and ma<strong>in</strong>tenance practices, thewire rope end term<strong>in</strong>ation should be <strong>in</strong>spected periodicallyfor wear, abuse, and general adequacy.table IclIP MInIMUM aMoUnt of *toRQUe InsIze no. RoPe to tURn ft.(In.) of clIPs back In <strong>Inc</strong>Hes (lbs)1/8 2 3-1/4 4.53/16 2 3-3/4 7.51/4 2 4-3/4 155/16 2 5-1/4 303/8 2 6-1/2 457/16 2 7 651/2 3 11-1/2 659/16 3 12 955/8 3 12 953/4 4 18 1307/8 4 19 2251 5 26 2251-1/8 6 34 2251-1/4 7 44 3601-3/8 7 44 3601-1/2 8 4 3601-5/8 8 58 4301-3/4 8 61 5902 8 71 7502-1/4 8 73 7502-1/2 9 84 7502-3/4 10 100 7503 10 106 12003-1/2 12 149 1200If a pulley (sheave) is used for turn<strong>in</strong>g back the wire rope, add oneadditional clip.If a greater number of clips are used than shown <strong>in</strong> the table, theamount of turnback should be <strong>in</strong>creased proportionately.*The tighten<strong>in</strong>g torque values shown are based upon the threadsbe<strong>in</strong>g clean, dry, and free of lubrication.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com85