twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

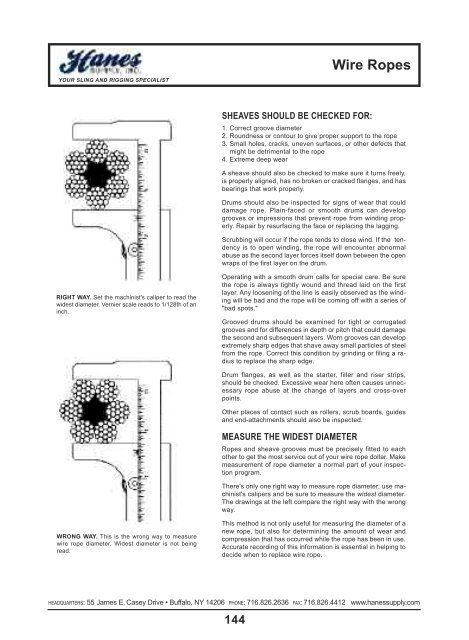

YOUR SLING AND RIGGING SPECIALISTWire RopesSHEAVES SHOULD BE CHECKED FOR:1. Correct groove diameter2. Roundness or contour to give proper support to the rope3. Small holes, cracks, uneven surfaces, or other defects thatmight be detrimental to the rope4. Extreme deep wearA sheave should also be checked to make sure it turns freely,is properly aligned, has no broken or cracked flanges, and hasbear<strong>in</strong>gs that work properly.Drums should also be <strong>in</strong>spected for signs of wear that coulddamage rope. Pla<strong>in</strong>-faced or smooth drums can developgrooves or impressions that prevent rope from w<strong>in</strong>d<strong>in</strong>g properly.Repair by resurfac<strong>in</strong>g the face or replac<strong>in</strong>g the lagg<strong>in</strong>g.Scrubb<strong>in</strong>g will occur if the rope tends to close w<strong>in</strong>d. If the tendencyis to open w<strong>in</strong>d<strong>in</strong>g, the rope will encounter abnormalabuse as the second layer forces itself down between the openwraps of the first layer on the drum.RIGHt WaY. Set the mach<strong>in</strong>ist's caliper to read thewidest diameter. Vernier scale reads to 1/128th of an<strong>in</strong>ch.Operat<strong>in</strong>g with a smooth drum calls for special care. Be surethe rope is always tightly wound and thread laid on the firstlayer. Any loosen<strong>in</strong>g of the l<strong>in</strong>e is easily observed as the w<strong>in</strong>d<strong>in</strong>gwill be bad and the rope will be com<strong>in</strong>g off with a series of"bad spots."Grooved drums should be exam<strong>in</strong>ed for tight or corrugatedgrooves and for differences <strong>in</strong> depth or pitch that could damagethe second and subsequent layers. Worn grooves can developextremely sharp edges that shave away small particles of steelfrom the rope. Correct this condition by gr<strong>in</strong>d<strong>in</strong>g or fil<strong>in</strong>g a radiusto replace the sharp edge.Drum flanges, as well as the starter, filler and riser strips,should be checked. Excessive wear here often causes unnecessaryrope abuse at the change of layers and cross-overpo<strong>in</strong>ts.Other places of contact such as rollers, scrub boards, guidesand end-attachments should also be <strong>in</strong>spected.MEASURE THE WIDEST DIAMETERRopes and sheave grooves must be precisely fitted to eachother to get the most service out of your wire rope dollar. Makemeasurement of rope diameter a normal part of your <strong>in</strong>spectionprogram.There's only one right way to measure rope diameter: use mach<strong>in</strong>ist'scalipers and be sure to measure the widest diameter.The draw<strong>in</strong>gs at the left compare the right way with the wrongway.WRonG WaY. This is the wrong way to measurewire rope diameter. Widest diameter is not be<strong>in</strong>gread.This method is not only useful for measur<strong>in</strong>g the diameter of anew rope, but also for determ<strong>in</strong><strong>in</strong>g the amount of wear andcompression that has occurred while the rope has been <strong>in</strong> use.Accurate record<strong>in</strong>g of this <strong>in</strong>formation is essential <strong>in</strong> help<strong>in</strong>g todecide when to replace wire rope.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com144