twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

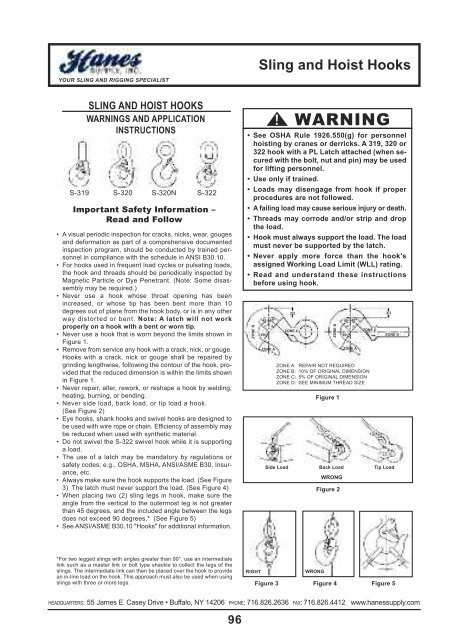

YOUR SLING AND RIGGING SPECIALISTsl<strong>in</strong>g and Hoist HooksSLING AND HOIST HOOKSWARNINGS AND APPLICATIONINSTRUCTIONSS-319 S-320 S-320N S-322Important Safety Information –Read and Follow• A visual periodic <strong>in</strong>spection for cracks, nicks, wear, gougesand deformation as part of a comprehensive documented<strong>in</strong>spection program, should be conducted by tra<strong>in</strong>ed personnel<strong>in</strong> compliance with the schedule <strong>in</strong> ANSI B30.10.• For hooks used <strong>in</strong> frequent load cycles or pulsat<strong>in</strong>g loads,the hook and threads should be periodically <strong>in</strong>spected byMagnetic Particle or Dye Penetrant. (Note: Some disassemblymay be required.)• Never use a hook whose throat open<strong>in</strong>g has been<strong>in</strong>creased, or whose tip has been bent more than 10degrees out of plane from the hook body, or is <strong>in</strong> any otherway distorted or bent. note: a latch will not workproperly on a hook with a bent or worn tip.• Never use a hook that is worn beyond the limits shown <strong>in</strong>Figure 1.• Remove from service any hook with a crack, nick, or gouge.Hooks with a crack, nick or gouge shall be repaired bygr<strong>in</strong>d<strong>in</strong>g lengthwise, follow<strong>in</strong>g the contour of the hook, providedthat the reduced dimension is with<strong>in</strong> the limits shown<strong>in</strong> Figure 1.• Never repair, alter, rework, or reshape a hook by weld<strong>in</strong>g,heat<strong>in</strong>g, burn<strong>in</strong>g, or bend<strong>in</strong>g.• Never side load, back load, or tip load a hook.(See Figure 2)• Eye hooks, shank hooks and swivel hooks are designed tobe used with wire rope or cha<strong>in</strong>. Efficiency of assembly maybe reduced when used with synthetic material.• Do not swivel the S-322 swivel hook while it is support<strong>in</strong>ga load.• The use of a latch may be mandatory by regulations orsafety codes; e.g., OSHA, MSHA, ANSI/ASME B30, Insurance,etc.• Always make sure the hook supports the load. (See Figure3) The latch must never support the load. (See Figure 4)• When plac<strong>in</strong>g two (2) sl<strong>in</strong>g legs <strong>in</strong> hook, make sure theangle from the vertical to the outermost leg is not greaterthan 45 degrees, and the <strong>in</strong>cluded angle between the legsdoes not exceed 90 degrees.* (See Figure 5)• See ANSI/ASME B30.10 "Hooks" for additional <strong>in</strong>formation.• see osHa Rule 1926.550(g) for personnelhoist<strong>in</strong>g by cranes or derricks. a 319, 320 or322 hook with a Pl latch attached (when securedwith the bolt, nut and p<strong>in</strong>) may be usedfor lift<strong>in</strong>g personnel.• Use only if tra<strong>in</strong>ed.• loads may disengage from hook if properprocedures are not followed.• a fail<strong>in</strong>g load may cause serious <strong>in</strong>jury or death.• threads may corrode and/or strip and dropthe load.• Hook must always support the load. the loadmust never be supported by the latch.• never apply more force than the hook'sassigned Work<strong>in</strong>g load limit (Wll) rat<strong>in</strong>g.• Read and understand these <strong>in</strong>structionsbefore us<strong>in</strong>g hook.zone b45°60°zone a!45°2/3zone cWARNINGZONE A: REPAIR NOT REQUIREDZONE B: 10% OF ORIGINAL DIMENSIONZONE C: 5% OF ORIGINAL DIMENSIONZONE D: SEE MINIMUM THREAD SIZEfigure 1side load back load tip loadWRonGzone bfigure 245°45°zone azone c2/360° zone D*For two legged <strong>sl<strong>in</strong>gs</strong> with angles greater than 90°, use an <strong>in</strong>termediatel<strong>in</strong>k such as a master l<strong>in</strong>k or bolt type shackle to collect the legs of the<strong>sl<strong>in</strong>gs</strong>. The <strong>in</strong>termediate l<strong>in</strong>k can then be placed over the hook to providean <strong>in</strong>-l<strong>in</strong>e load on the hook. This approach must also be used when us<strong>in</strong>g<strong>sl<strong>in</strong>gs</strong> with three or more legs.RIGHtWRonGfigure 3 figure 4 figure 5HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com96