twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

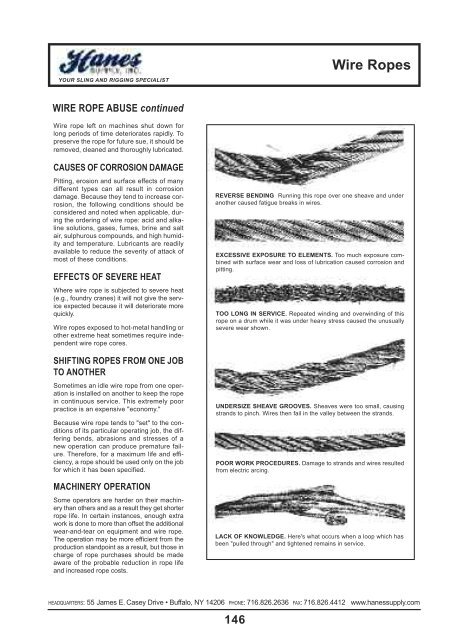

YOUR SLING AND RIGGING SPECIALISTWire RopesWIRE ROPE ABUSE cont<strong>in</strong>uedWire rope left on mach<strong>in</strong>es shut down forlong periods of time deteriorates rapidly. Topreserve the rope for future sue, it should beremoved, cleaned and thoroughly lubricated.CAUSES OF CORROSION DAMAGEPitt<strong>in</strong>g, erosion and surface effects of manydifferent types can all result <strong>in</strong> corrosiondamage. Because they tend to <strong>in</strong>crease corrosion,the follow<strong>in</strong>g conditions should beconsidered and noted when applicable, dur<strong>in</strong>gthe order<strong>in</strong>g of wire rope: acid and alkal<strong>in</strong>esolutions, gases, fumes, br<strong>in</strong>e and saltair, sulphurous compounds, and high humidityand temperature. Lubricants are readilyavailable to reduce the severity of attack ofmost of these conditions.EFFECTS OF SEVERE HEATWhere wire rope is subjected to severe heat(e.g., foundry cranes) it will not give the serviceexpected because it will deteriorate morequickly.Wire ropes exposed to hot-metal handl<strong>in</strong>g orother extreme heat sometimes require <strong>in</strong>dependentwire rope cores.SHIFTING ROPES FROM ONE JOBTO ANOTHERSometimes an idle wire rope from one operationis <strong>in</strong>stalled on another to keep the rope<strong>in</strong> cont<strong>in</strong>uous service. This extremely poorpractice is an expensive "economy."Because wire rope tends to "set" to the conditionsof its particular operat<strong>in</strong>g job, the differ<strong>in</strong>gbends, abrasions and stresses of anew operation can produce premature failure.Therefore, for a maximum life and efficiency,a rope should be used only on the jobfor which it has been specified.MACHINERY OPERATIONSome operators are harder on their mach<strong>in</strong>erythan others and as a result they get shorterrope life. In certa<strong>in</strong> <strong>in</strong>stances, enough extrawork is done to more than offset the additionalwear-and-tear on equipment and wire rope.The operation may be more efficient from theproduction standpo<strong>in</strong>t as a result, but those <strong>in</strong>charge of rope purchases should be madeaware of the probable reduction <strong>in</strong> rope lifeand <strong>in</strong>creased rope costs.ReVeRse benDInG Runn<strong>in</strong>g this rope over one sheave and underanother caused fatigue breaks <strong>in</strong> wires.eXcessIVe eXPosURe to eleMents. Too much exposure comb<strong>in</strong>edwith surface wear and loss of lubrication caused corrosion andpitt<strong>in</strong>g.too lonG In seRVIce. Repeated w<strong>in</strong>d<strong>in</strong>g and overw<strong>in</strong>d<strong>in</strong>g of thisrope on a drum while it was under heavy stress caused the unusuallysevere wear shown.UnDeRsIze sHeaVe GRooVes. Sheaves were too small, caus<strong>in</strong>gstrands to p<strong>in</strong>ch. Wires then fail <strong>in</strong> the valley between the strands.PooR WoRk PRoceDURes. Damage to strands and wires resultedfrom electric arc<strong>in</strong>g.lack of knoWleDGe. Here's what occurs when a loop which hasbeen "pulled through" and tightened rema<strong>in</strong>s <strong>in</strong> service.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com146