twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

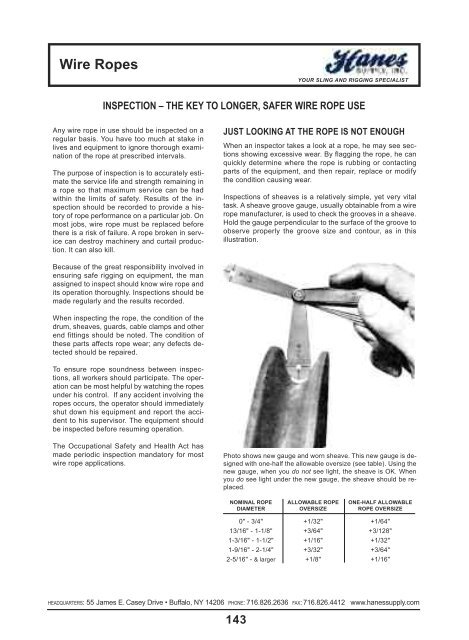

Wire RopesYOUR SLING AND RIGGING SPECIALISTINSPECTION – THE KEY TO LONGER, SAFER WIRE ROPE USEAny wire rope <strong>in</strong> use should be <strong>in</strong>spected on aregular basis. You have too much at stake <strong>in</strong>lives and equipment to ignore thorough exam<strong>in</strong>ationof the rope at prescribed <strong>in</strong>tervals.The purpose of <strong>in</strong>spection is to accurately estimatethe service life and strength rema<strong>in</strong><strong>in</strong>g <strong>in</strong>a rope so that maximum service can be hadwith<strong>in</strong> the limits of safety. Results of the <strong>in</strong>spectionshould be recorded to provide a historyof rope performance on a particular job. Onmost jobs, wire rope must be replaced beforethere is a risk of failure. A rope broken <strong>in</strong> servicecan destroy mach<strong>in</strong>ery and curtail production.It can also kill.JUST LOOKING AT THE ROPE IS NOT ENOUGHWhen an <strong>in</strong>spector takes a look at a rope, he may see sectionsshow<strong>in</strong>g excessive wear. By flagg<strong>in</strong>g the rope, he canquickly determ<strong>in</strong>e where the rope is rubb<strong>in</strong>g or contact<strong>in</strong>gparts of the equipment, and then repair, replace or modifythe condition caus<strong>in</strong>g wear.Inspections of sheaves is a relatively simple, yet very vitaltask. A sheave groove gauge, usually obta<strong>in</strong>able from a wirerope manufacturer, is used to check the grooves <strong>in</strong> a sheave.Hold the gauge perpendicular to the surface of the groove toobserve properly the groove size and contour, as <strong>in</strong> thisillustration.Because of the great responsibility <strong>in</strong>volved <strong>in</strong>ensur<strong>in</strong>g safe rigg<strong>in</strong>g on equipment, the manassigned to <strong>in</strong>spect should know wire rope andits operation thoroughly. Inspections should bemade regularly and the results recorded.When <strong>in</strong>spect<strong>in</strong>g the rope, the condition of thedrum, sheaves, guards, cable clamps and otherend fitt<strong>in</strong>gs should be noted. The condition ofthese parts affects rope wear; any defects detectedshould be repaired.To ensure rope soundness between <strong>in</strong>spections,all workers should participate. The operationcan be most helpful by watch<strong>in</strong>g the ropesunder his control. If any accident <strong>in</strong>volv<strong>in</strong>g theropes occurs, the operator should immediatelyshut down his equipment and report the accidentto his supervisor. The equipment shouldbe <strong>in</strong>spected before resum<strong>in</strong>g operation.The Occupational Safety and Health Act hasmade periodic <strong>in</strong>spection mandatory for mostwire rope applications.Photo shows new gauge and worn sheave. This new gauge is designedwith one-half the allowable oversize (see table). Us<strong>in</strong>g thenew gauge, when you do not see light, the sheave is OK. Whenyou do see light under the new gauge, the sheave should be replaced.noMInal RoPe alloWable RoPe one-Half alloWableDIaMeteR oVeRsIze RoPe oVeRsIze0" - 3/4" +1/32" +1/64"13/16" - 1-1/8" +3/64" +3/128"1-3/16" - 1-1/2" +1/16" +1/32"1-9/16" - 2-1/4" +3/32" +3/64"2-5/16" - & larger +1/8" +1/16"HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com143